-

COVID 19 The State Of Supply Chains (Part 2)

The shutdowns and disruptions from COVID-19 outbreaks have forever changed the way consumers, retailers, and suppliers work and operate. And the problems created are still being dealt with throughout the supply chain. Companies must accelerate global strategies to customer service and inventory planning processes and management.

It is crucial to understand the problems faced within the global supply chain when it comes to being able to meet customer expectations, contract supply issues, and demand concerns. E-commerce challenges continue to pose a problem as ongoing growth and recovery efforts continue. And those problems will only continue. According to the United Nations Conference on Trade and Development (UNCTAD), COVID-19 pushed e-commerce to $27.6 trillion by early 2021.

Transportation companies must understand why these problems had a significant impact on supply chains across many different companies. It is only when issues and their origin are understood in detail, effective and adequate solutions can be implemented to prevent the return of future negative effects within global commerce.

Now that the negative effects are known and understood to a degree, companies are starting to implement countermeasures. The leading issue supply chains across companies have issues with coping with the impact of the pandemic lies at the current/prior resilience level.

Companies that wish to accelerate global demand planning and supply chain operations need to focus on known issues and improve end to end resilience.

The first part of this article described the negative effects on Supply Chains as a result of COVID-19. It is crucial to understand the problems faced and the reasoning as to why these problems had a big impact amongst Supply Chains across many different companies. It is only when problems and their origin are understood in detail, effective and adequate solutions can be implemented to prevent the return of future negative effects.

Now that the negative effects are known and understood to a degree, companies are starting to implement counter measures. Of course, the type of measure implemented depends on the specific company in question. However, the main issue Supply Chains across companies have issues with coping with the effects of the pandemic lies at the current/prior resilience level. Supply Chains simply did not invest sufficiently in the resilience element to minimize these negative effects. Now, how can companies specifically improve their Supply Chain Resilience?

How Can Companies Improve Their Supply Chain Resilience?

The pandemic will not disappear anytime soon. To improve resilience, companies require steady, start-to-finish appraisal and enhancement, and observation. Robust global commerce analytical systems must monitor constant changes in the marketplace to ensure optimal order processing by a fulfillment partner.

Strong analytical capacity will allow companies to understand the complexity of contract supply better, anticipate potential disruption, and quickly develop a response (BizClik Media, 2020).

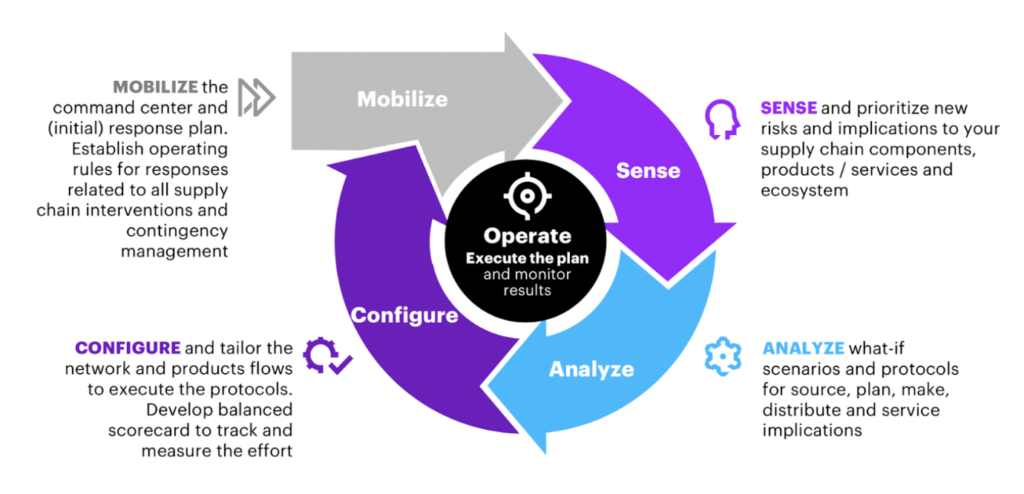

See the figure below for a clear visual on how to improve supply chain planning and supply chain processes in a structured way.

Figure 1 Operate – Execute – Monitor Cycle (Resilience) https://supplychaindigital.com/supply-chain-2/accenture-building-supply-chain-resilience-amidst-covid-19

Steps to Accelerate Global Supply Chain Performance

Let’s create a scenario on how to improve the Supply Chain’s resilience using the diagram above. Remember, the end goal of increased Resilience is necessary to enable and increase a company’s ability to respond accordingly to unexpected changes within the demand/marketplace.

Supply chain management is all about looking for ways to improve key performance metrics. The following steps can help in short term and long term goals.

Step 1: Mobilize

To counter unexpected changes in demand, an initial response plan must be in place that holds specific operating rules. For instance, if demand rises above level X%, automatic notifications must be sent to suppliers A/B to deliver new products on time.

These resilience supply parameters can be established based on safety/stock margins resulting from product priority and lead times to accelerate global metrics. Regular flow and depreciation value also play essential roles in determining these specific parameters.

Step 2: Sense

After creating the fundamental counterplan, risks and implications on the Supply Chain must be identified and analyzed as soon as possible. For instance, if Supplier A uses a specific raw material to create a product known to become scarce upon demand increase, inform yourself about alternatives that enable product delivery past these scarcity levels.

Diversify risks by looking for ways to counter transportation costs and concerns in global commerce, production, and delivery. This is critical for domestic, global, and cross-border processes.

Step 3: Analyze

It is essential to analyze ‘what-if’ scenarios in case of unexpected plan failures. It is best to review these plans and procedures every couple of months, depending on the company, to ensure their validity.

Furthermore, having multiple perceptions on/off the scenarios and solutions may contribute to increased quality and resilience. The more a company asks itself what if x will happen, especially when analyzing contract supply metrics for inventory levels and product designs, the better the understanding of the possible unexpected obstructions.

Step 4: Configure

This final step of this never-ending cycle should include the configuration of the entire counter process. All steps/elements needed to facilitate the counterplan should be in place. New transport/backup modalities, alternate materials, backup machinery, etc.

The more extensive the preparation, the better. This last step ties in with the third analysis step, as the potential disruptive scenarios accelerate global configuration needs.

Improve Global Commerce Performance With ModusLink

After continuous focus on Supply Chain optimization to minimize costs and improve efficiency across the board, COVID-19 clearly illustrates that many companies are not fully aware of the vulnerability of their supply chain relationships to unexpected Global changes within the marketplace/demand (Deloitte, 2021).

Fortunately, new digitalized Supply Chain technologies are showing potential to drastically improve the visibility across the end-to-end supply chain. It is clear that the current linear model of Supply Chains was not sufficient to be resistant to such global changes as the pandemic. Technologies such as the Internet of Things, artificial intelligence, AVG (Automated Guided Vehicles) are designed to anticipate and meet future challenges.

Would you like to know more about the state of Supply Chains moving forward? Stay tuned for our next Blog where we will go more in-depth or talk to a ModusLink Expert today by clicking here!.

Bibliography:

(2021, May 3). Global e-commerce jumps to $26.7 trillion, COVID-19 boosts online sales, Accessed October 20, 2022 From https://unctad.org/news/global-e-commerce-jumps-267-trillion-covid-19-boosts-online-sales

BizClik Media. (2020, May 17). Accenture: building supply chain resilience amidst COVID-19. Supply Chain Digital. Retrieved November 27, 2021, from https://supplychaindigital.com/supply-chain-2/accenture-building-supply-chain-resilience-amidst-covid-19

COVID-19: Managing supply chain risk and disruption. (2021, October 5). Deloitte. Retrieved November 26, 2021, from https://www2.deloitte.com/global/en/pages/risk/cyber-strategic-risk/articles/covid-19-managing-supply-chain-risk-and-disruption.html

G. (n.d.). What impact has COVID-19 had on supply chains & responsible sourcing? Greenstone. Retrieved November 26, 2021, from https://www.greenstoneplus.com/blog/what-impact-has-covid-19-had-on-supply-chains-responsible-sourcing

Gilkey, J. G. (2021, May 1). The challenges and realities of retailing in a COVID-19 world. Researchgate. Retrieved November 28, 2021, from https://www.researchgate.net/publication/351656064_The_challenges_and_realities_of_retailing_in_a_COVID-19_world_Identifying_trending_and_Vital_During_Crisis_keywords_during_Covid-19_using_Machine_Learning_Austria_as_a_case_study

Harapko, S. H. (2021, February 18). supply-chain. Ey.Com. Retrieved November 26, 2021, from https://www.ey.com/en_gl/supply-chain/how-covid-19-impacted-supply-chains-and-what-comes-next

Meyer, A. (n.d.). The Impact of the Coronavirus Pandemic on Supply Chains and Their Sustainability: A Text Mining Approach. Frontiers. Retrieved November 26, 2021, from https://www.frontiersin.org/articles/10.3389/frsus.2021.631182/full

Netherlands, S. (2021, July 27). COVID-19 impact on supply chains. Statistics Netherlands. Retrieved November 25, 2021, from https://www.cbs.nl/en-gb/dossier/coronavirus-crisis-cbs-figures/covid-19-impact-on-supply-chains

-

COVID 19 The State Of Supply Chains (Part 1)

With all the upheaval that global supply chains have had to contend with, the value of supply chain optimization has never been more vital. Significant progress has been made over the last two years to respond to the weaknesses and issues exposed, but there is still much to be done regarding supply chain strategies and implementation. Approaching logistics with a focus on omnichannel supply chain options may be the best option to speed recovery.

As highlighted by McKinsey & Company in late 2021, “Companies have only partly addressed the weaknesses in global supply chains exposed by the coronavirus pandemic. In the face of new challenges, finishing the job is even more urgent.” This is where a service now and omnichannel approach can make all the difference for logistics managers when it comes to recovery from the pandemic’s disruption. Many companies in the world today struggle with this aspect of supply chain operations and business strategy. But it doesn’t have to be this way.

Covid-19: The Grand Disruption

Delayed shipments because of sea freight disruptions, monthly increasing fuel charges, challenges with supply chain optimization, and disconnected communication between transport modalities.. These are all direct effects encountered across supply networks, from technology companies to fleet managers to retail distributors, that resulted from introducing the virus COVID-19.

Companies need a service now and omnichannel approach to logistics to maintain a competitive advantage. It is undeniable that COVID-19 has caused many disruptions across markets.

Especially within the supply chain industry, the virus has caused some companies to go bankrupt due to their fragile supply chain and product development and distribution processes. They simply have not been able to counter the adverse effects caused by the virus.

Many high paying logistics jobs offer an opportunity to improve the industry as a whole and impact future developments within the supply chain network. This unforeseen situation, experienced by companies worldwide, has caused management staff to revisit and revise their current strategies.

What is the current state of supply chains? Are there any positive effects of poor supply chain optimization and disruption? Which are the critical learning factors to pay attention to? How has CRM and other platform innovations impacted the supply chain?

These questions are covered here so supply chain managers and team members can better understand the state of the supply chain industry today as the world continues to recover from COVID-19.

Negative Effects on Supply Chain Optimization

To understand the current state of supply chains the negative effects incurred must be known. Many Supply Chains faced comparable negative issues because of COVID-19.

Ernst & Young LLP (EY US) surveyed in late 2020 where asked approximately 200 senior-level supply chain executives at organizations across many sectors. This includes consumer products, retail, life sciences, industrial products, automotive, and high-tech companies in the United States with over US$1b in revenues within the service now and omnichannel platforms.

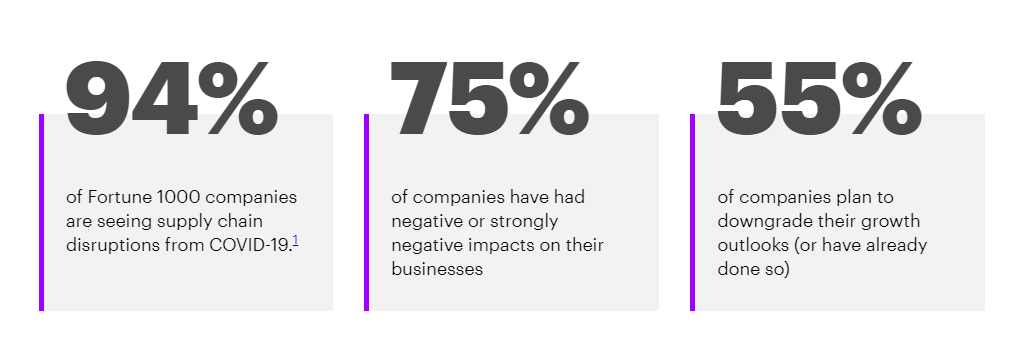

Some of these responders were looking at high paying logistics jobs and how to improve the supply chain operations. See the chart below (Harapko, 2021).

According to this research into supply chain optimization, the pandemic hit shippers, carriers, and transportation companies hard. Some companies experienced more negative effects than others. This research stated that, among the respondents, all automotive and nearly all (97%) industrial product companies said the pandemic negatively affected them.Furthermore, 47% of all companies reported the pandemic disrupted their workforce. These are significant amounts and visualize the struggle experienced by many companies in their later stages. Recovery efforts will likely continue for years to come as the full impact of global shutdowns, closures, backlogs, and disruptions still impact nearly every industry from brick and mortar to e-commerce businesses.

Confusion Fueled by a Lack of Understanding

The specific adverse effects Supply Chains face are too many to go into detail—supplier retraction, fuel charge increases, modality issues, supply chain optimization issues etc.

As a result, the impact of the adverse effects stated accumulated rapidly. It was difficult to implement direct countermeasures as nobody understood precisely how the virus would develop in the future.

According to Greenstone (n.d.), this confusion and lack of understanding resulted in cross-border flows of goods being stalled due to safety precautions needing to be understood and then implemented.

Furthermore, local ‘lockdown’ regulations formed a great obstacle that needed to be understood about trade. Only after this could the natural flow-of-goods continue to work on service now and omnichannel operating levels.

This phenomenon can be easily identified within supply lines and logistical routes. However, as mentioned before, the negative effects of these high-paying logistics jobs can be seen across all industries. Fortune magazine noted that nearly 94% of the Fortune 500 companies claim to see supply chain disruptions because of the coronavirus. Implementing new processes for digitization and automation can improve recovery efforts for businesses of all sizes.

Figure 2 COVID-19 Supply Chain effects – Fortune 1000 companies (https://www.google.com/url?sa=i&url=https%3A%2F%2Fsupplychaindigital.com%2Fsupply-chain-2%2Faccenture-building-supply-chain-resilience-amidst-covid-19&psig=AOvVaw1cleCCNUnB1vy8TfDrQvHx&ust=16388950

Overcome the Impacts of COVID-19 With Help From ModusLink

The main conclusion that can be given from the experienced negative effects is that many companies lacked a certain amount of resilience within their supply chain optimization processes and supply chain structure.

On the upside, COVID-19 has magnified and identified the present issues within current/former supply chain structures and operations. Now that these issues have been identified, companies can use this knowledge to adjust accordingly for the better and gain a solid competitive advantage as a result.

When you have products and services to offer, you want to ensure your company is up to the task. Dealing with short term and long term effects of the global pandemic is a serious task for any company to overcome.

Would you like to know more about the state of supply chains moving forward and how supply chain optimization continues to impact the industry? Contact a ModusLink expert today to get started.

Bibliography:

Alike, Knut, Barriball, Ed, Trautweign, Vera (2021, November 23) How COVID-19 is reshaping supply chains, Accessed October 22, 2022 From https://www.mckinsey.com/capabilities/operations/our-insights/how-covid-19-is-reshaping-supply-chains

2021, May 3). Global e-commerce jumps to $26.7 trillion, COVID-19 boosts online sales, Accessed October 20, 2022 From https://unctad.org/news/global-e-commerce-jumps-267-trillion-covid-19-boosts-online-sales

BizClik Media. (2020, May 17). Accenture: building supply chain resilience amidst COVID-19. Supply Chain Digital. Retrieved November 27, 2021, from https://supplychaindigital.com/supply-chain-2/accenture-building-supply-chain-resilience-amidst-covid-19

COVID-19: Managing supply chain risk and disruption. (2021, October 5). Deloitte. Retrieved November 26, 2021, from https://www2.deloitte.com/global/en/pages/risk/cyber-strategic-risk/articles/covid-19-managing-supply-chain-risk-and-disruption.html

G. (n.d.). What impact has COVID-19 had on supply chains & responsible sourcing? Greenstone. Retrieved November 26, 2021, from https://www.greenstoneplus.com/blog/what-impact-has-covid-19-had-on-supply-chains-responsible-sourcing

Gilkey, J. G. (2021, May 1). The challenges and realities of retailing in a COVID-19 world. Researchgate. Retrieved November 28, 2021, from https://www.researchgate.net/publication/351656064_The_challenges_and_realities_of_retailing_in_a_COVID-19_world_Identifying_trending_and_Vital_During_Crisis_keywords_during_Covid-19_using_Machine_Learning_Austria_as_a_case_study

Harapko, S. H. (2021, February 18). supply-chain. Ey.Com. Retrieved November 26, 2021, from https://www.ey.com/en_gl/supply-chain/how-covid-19-impacted-supply-chains-and-what-comes-next

Meyer, A. (n.d.). The Impact of the Coronavirus Pandemic on Supply Chains and Their Sustainability: A Text Mining Approach. Frontiers. Retrieved November 26, 2021, from https://www.frontiersin.org/articles/10.3389/frsus.2021.631182/full

Netherlands, S. (2021, July 27). COVID-19 impact on supply chains. Statistics Netherlands. Retrieved November 25, 2021, from https://www.cbs.nl/en-gb/dossier/coronavirus-crisis-cbs-figures/covid-19-impact-on-supply-chains

-

Inventory Management & Supply Chain Responsiveness

nventory management has always played a key part in any successful supply chain process. Managing inventory levels helps companies to swiftly adapt to unpredictable changes within the marketplace. Volatile demand can cause troubling issues when not handled correctly. That undermines supply chain performance and customer relationship management. When there are weaknesses in how managers link warehouse operations and manage supply chain innovation, the risk increases. In fact, 56% of business leaders still report inefficient inventory management capabilities, asserts Forbes. Let’s take a closer look at how your company can improve inventory management to boost customer experiences, purchase orders, and small business efficiencies.

The Importance of Inventory Management in Public Warehouse Operations

Digitization and automation are at the heart of ongoing growth and recovery and can help businesses overcome common warehousing and inventory issues. For instance, let’s say you are a company that sells seasonal jackets. Due to an unusually warm winter, your winter jackets no longer sell as expected.

Without adapting to the current demand, your winter jackets will become excess inventory over time. Using up public warehouse space to sort, organize, and store excess inventory can get costly.

These negative effects could have been prevented with an adaptive and responsive supply chain across all industries. Knowing how to link warehouse centers, supply lines, and shipping lanes efficiently can improve management and logistics for supply chains.

For example, retail and spa warehouse needs may vary greatly, but they all must still rely on data to track operational efficiency. It is crucial for all businesses looking to scale, to understand the importance of having the ability to shift production toward demand.

Steps to Take for Better Supply Chain Responsiveness And to Link Warehouse Operations

Correctly managing inventory levels and knowing how to effectively link warehouses requires a responsive supply chain, but what exactly does that mean?

According to IGI Global(n.d.), a strong supply network can be defined as a supply chain that is able to shift its production to unpredictable customer demand. How do supply chains do this?

One way to realize a responsive network is to correctly manage logistics warehouse and inventory levels..

Boost Inventory Management

Correctly managing Inventory levels can be a struggle, depending on the marketplace and products in question. See below the best ways you can effectively improve your inventory management by making your logistics warehouse processes more responsive.

Working with the best fulfillment partner can ensure inventory management remains front and center at all times. It allows companies to better regulate inventory and keep up with critical supply chain processes. This focus makes optimization and responsiveness much easier.

Improve Supplier relationships

Products that require multiple raw materials or parts from different suppliers are heavily reliant on active supplier relationships. Companies that trade in those products ought to continuously look for ways to improve their supplier relationships, including public warehouse access and utilization.

Having a better understanding of your supplier’s business position (and vice versa) allows a company to better anticipate and forecast possible disruptions and improve the way they coordinate and link warehouses and other applicable chain parties. This maximizes the throughput speed at which new materials can be ordered and received, in turn increasing your adaptability to the marketplace. Having access to the best supply chain tools can also help significantly. .

Figure 1(Supplier Relationship Management) Significance of Healthy Supplier Relationship. (n.d.). from http://www.strategicsourcing.pk/2015/12/significance-of-healthy-supplier.html

Enhance Risk Management

Another way to improve inventory control and build supply chain responsiveness is through effective risk management. Especially in turbulent times and strong unforeseen events such as COVID-19, the element of risk management is crucial for any business looking for ways to boost logistics warehouse operations and streamline operations.

Especially for SMEs (Small-Medium-Enterprises) looking to invest in new technology, a detailed risk analogy of the sought-after investment must always be made prior to continuing business. Automation and digitalization are important elements in linked warehouses nowadays. Despite the importance of these elements, never invest without proper risk-return analysis.

Consider Outsourcing Options

A method to the improvement of performance and inventory management that has become increasingly popular over the years is the concept of outsourcing. Companies such as ModusLink are industry experts with years of industry experience and knowledge regarding public warehouse and inventory management processes.

Companies that rely on warehouse and distribution services need sound logistics warehouse management processes. Without a solid foundation, the entire network will struggle from the start. For many companies, the easiest solution to this shortcoming is to outsource services.

Looking Forward to Future Growth and Success

Some companies today can also be price-competitive, increasing the attractiveness of outsourcing your supply chain. These companies use their extensive network, supplier relationships, and vast IT infrastructure to massively increase supply chain responsiveness and inventory management processes. They understand the importance of linked warehouse operations.

Companies that outsource effectively gain the ability to spend resources elsewhere. This allows their business to flourish in a short-time period and more importantly, increases their ability to scale effectively. The effects of COVID-19 have forever changed the market and how consumers shop, which has forever altered how inventory management and supply chain responsiveness is measured.

Improve Logistics Warehouse Operations With ModusLink

These three elements are important ways to Increase a supply chain’s responsiveness and in turn, increase inventory management. There are plenty of other ways a business can improve its supply chain strategy and boost the ability to link warehouses effectively.

Would you like to know more about these innovative strategies and how to improve supply chain operations with enhanced inventory management? Contact ModusLink today to learn more and to see how easy inventory management can be when you have the right tools and guidance!

Bibliography:

Amsler, S., O’Donnell, J., & Cole, B. (2021, February 11). inventory management. SearchERP. Retrieved November 24, 2021, from https://searcherp.techtarget.com/definition/inventory-management

Significance of Healthy Supplier Relationship. (n.d.). Strategic Sourcing. Retrieved December 3, 2021, from http://www.strategicsourcing.pk/2015/12/significance-of-healthy-supplier.html

Walts, A. (2021, October 29). Your Essential Guide to Effective Inventory Management + 18 Techniques You Need to Know. The BigCommerce Blog. Retrieved November 21, 2021, from https://www.bigcommerce.com/blog/inventory-management/

What is Responsive Supply Chain | IGI Global. (n.d.). IGI. Retrieved December 3, 2021, from https://www.igi-global.com/dictionary/building-a-strategic-framework-for-retail-supply-chain-analytics/52748