The shutdowns and disruptions from COVID-19 outbreaks have forever changed the way consumers, retailers, and suppliers work and operate. And the problems created are still being dealt with throughout the supply chain. Companies must accelerate global strategies to customer service and inventory planning processes and management.

It is crucial to understand the problems faced within the global supply chain when it comes to being able to meet customer expectations, contract supply issues, and demand concerns. E-commerce challenges continue to pose a problem as ongoing growth and recovery efforts continue. And those problems will only continue. According to the United Nations Conference on Trade and Development (UNCTAD), COVID-19 pushed e-commerce to $27.6 trillion by early 2021.

Transportation companies must understand why these problems had a significant impact on supply chains across many different companies. It is only when issues and their origin are understood in detail, effective and adequate solutions can be implemented to prevent the return of future negative effects within global commerce.

Now that the negative effects are known and understood to a degree, companies are starting to implement countermeasures. The leading issue supply chains across companies have issues with coping with the impact of the pandemic lies at the current/prior resilience level.

Companies that wish to accelerate global demand planning and supply chain operations need to focus on known issues and improve end to end resilience.

The first part of this article described the negative effects on Supply Chains as a result of COVID-19. It is crucial to understand the problems faced and the reasoning as to why these problems had a big impact amongst Supply Chains across many different companies. It is only when problems and their origin are understood in detail, effective and adequate solutions can be implemented to prevent the return of future negative effects.

Now that the negative effects are known and understood to a degree, companies are starting to implement counter measures. Of course, the type of measure implemented depends on the specific company in question. However, the main issue Supply Chains across companies have issues with coping with the effects of the pandemic lies at the current/prior resilience level. Supply Chains simply did not invest sufficiently in the resilience element to minimize these negative effects. Now, how can companies specifically improve their Supply Chain Resilience?

How Can Companies Improve Their Supply Chain Resilience?

The pandemic will not disappear anytime soon. To improve resilience, companies require steady, start-to-finish appraisal and enhancement, and observation. Robust global commerce analytical systems must monitor constant changes in the marketplace to ensure optimal order processing by a fulfillment partner.

Strong analytical capacity will allow companies to understand the complexity of contract supply better, anticipate potential disruption, and quickly develop a response (BizClik Media, 2020).

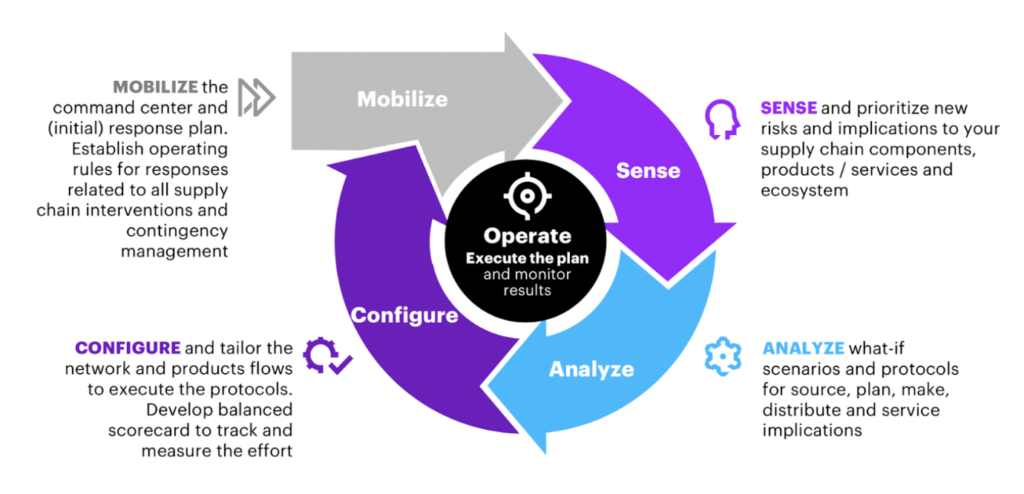

See the figure below for a clear visual on how to improve supply chain planning and supply chain processes in a structured way.

Figure 1 Operate – Execute – Monitor Cycle (Resilience) https://supplychaindigital.com/supply-chain-2/accenture-building-supply-chain-resilience-amidst-covid-19

Steps to Accelerate Global Supply Chain Performance

Let’s create a scenario on how to improve the Supply Chain’s resilience using the diagram above. Remember, the end goal of increased Resilience is necessary to enable and increase a company’s ability to respond accordingly to unexpected changes within the demand/marketplace.

Supply chain management is all about looking for ways to improve key performance metrics. The following steps can help in short term and long term goals.

Step 1: Mobilize

To counter unexpected changes in demand, an initial response plan must be in place that holds specific operating rules. For instance, if demand rises above level X%, automatic notifications must be sent to suppliers A/B to deliver new products on time.

These resilience supply parameters can be established based on safety/stock margins resulting from product priority and lead times to accelerate global metrics. Regular flow and depreciation value also play essential roles in determining these specific parameters.

Step 2: Sense

After creating the fundamental counterplan, risks and implications on the Supply Chain must be identified and analyzed as soon as possible. For instance, if Supplier A uses a specific raw material to create a product known to become scarce upon demand increase, inform yourself about alternatives that enable product delivery past these scarcity levels.

Diversify risks by looking for ways to counter transportation costs and concerns in global commerce, production, and delivery. This is critical for domestic, global, and cross-border processes.

Step 3: Analyze

It is essential to analyze ‘what-if’ scenarios in case of unexpected plan failures. It is best to review these plans and procedures every couple of months, depending on the company, to ensure their validity.

Furthermore, having multiple perceptions on/off the scenarios and solutions may contribute to increased quality and resilience. The more a company asks itself what if x will happen, especially when analyzing contract supply metrics for inventory levels and product designs, the better the understanding of the possible unexpected obstructions.

Step 4: Configure

This final step of this never-ending cycle should include the configuration of the entire counter process. All steps/elements needed to facilitate the counterplan should be in place. New transport/backup modalities, alternate materials, backup machinery, etc.

The more extensive the preparation, the better. This last step ties in with the third analysis step, as the potential disruptive scenarios accelerate global configuration needs.

Improve Global Commerce Performance With ModusLink

After continuous focus on Supply Chain optimization to minimize costs and improve efficiency across the board, COVID-19 clearly illustrates that many companies are not fully aware of the vulnerability of their supply chain relationships to unexpected Global changes within the marketplace/demand (Deloitte, 2021).

Fortunately, new digitalized Supply Chain technologies are showing potential to drastically improve the visibility across the end-to-end supply chain. It is clear that the current linear model of Supply Chains was not sufficient to be resistant to such global changes as the pandemic. Technologies such as the Internet of Things, artificial intelligence, AVG (Automated Guided Vehicles) are designed to anticipate and meet future challenges.

Would you like to know more about the state of Supply Chains moving forward? Stay tuned for our next Blog where we will go more in-depth or talk to a ModusLink Expert today by clicking here!.

Bibliography:

(2021, May 3). Global e-commerce jumps to $26.7 trillion, COVID-19 boosts online sales, Accessed October 20, 2022 From https://unctad.org/news/global-e-commerce-jumps-267-trillion-covid-19-boosts-online-sales

BizClik Media. (2020, May 17). Accenture: building supply chain resilience amidst COVID-19. Supply Chain Digital. Retrieved November 27, 2021, from https://supplychaindigital.com/supply-chain-2/accenture-building-supply-chain-resilience-amidst-covid-19

COVID-19: Managing supply chain risk and disruption. (2021, October 5). Deloitte. Retrieved November 26, 2021, from https://www2.deloitte.com/global/en/pages/risk/cyber-strategic-risk/articles/covid-19-managing-supply-chain-risk-and-disruption.html

G. (n.d.). What impact has COVID-19 had on supply chains & responsible sourcing? Greenstone. Retrieved November 26, 2021, from https://www.greenstoneplus.com/blog/what-impact-has-covid-19-had-on-supply-chains-responsible-sourcing

Gilkey, J. G. (2021, May 1). The challenges and realities of retailing in a COVID-19 world. Researchgate. Retrieved November 28, 2021, from https://www.researchgate.net/publication/351656064_The_challenges_and_realities_of_retailing_in_a_COVID-19_world_Identifying_trending_and_Vital_During_Crisis_keywords_during_Covid-19_using_Machine_Learning_Austria_as_a_case_study

Harapko, S. H. (2021, February 18). supply-chain. Ey.Com. Retrieved November 26, 2021, from https://www.ey.com/en_gl/supply-chain/how-covid-19-impacted-supply-chains-and-what-comes-next

Meyer, A. (n.d.). The Impact of the Coronavirus Pandemic on Supply Chains and Their Sustainability: A Text Mining Approach. Frontiers. Retrieved November 26, 2021, from https://www.frontiersin.org/articles/10.3389/frsus.2021.631182/full

Netherlands, S. (2021, July 27). COVID-19 impact on supply chains. Statistics Netherlands. Retrieved November 25, 2021, from https://www.cbs.nl/en-gb/dossier/coronavirus-crisis-cbs-figures/covid-19-impact-on-supply-chains