-

Mastering Demand-Driven Material Planning

Demand planning and data analysis concept. In the dynamic landscape of supply chain management, demand-driven material planning is a crucial strategy for optimizing operations and meeting customer demands efficiently. Let’s delve into the essentials of this approach and explore how businesses can successfully implement it with the expertise of ModusLink.

Understanding Demand-Driven Material Planning

Demand-driven material planning, often referred to as Demand-Driven Material Requirements Planning (DDMRP), is a strategic methodology that revolutionizes traditional supply chain practices. It combines elements of traditional MRP and lean principles to dynamically manage material requirements and inventory levels based on actual demand signals. The core of DDMRP lies in strategically positioning buffer stocks to enhance flow and reduce lead times, thus improving overall supply chain performance.

Key Strategies for Effective Demand-Driven Planning

- Accurate Demand Forecasting: Precise demand forecasting forms the foundation of demand-driven planning. ModusLink utilizes advanced analytics and historical data to develop accurate forecasts, ensuring the right quantity of packaging materials is available when needed.

- Flexible Inventory Management: Demand-driven planning emphasizes flexibility in inventory management. ModusLink’s solutions focus on maintaining optimal inventory levels, reducing excess stock, and minimizing holding costs through just-in-time practices.

- Supplier Collaboration: Collaborative partnerships with packaging material suppliers are vital. ModusLink fosters strong relationships to enable quick response times and flexible order quantities that align with demand fluctuations.

- Data-Driven Decision Making: Real-time data and analytics drive informed decision-making in demand-driven planning. ModusLink continuously monitors demand patterns, inventory levels, and supplier performance to optimize material planning strategies.

Implementing Demand-Driven Planning

Implementing demand-driven packaging material planning requires strategic partnerships with solution providers like ModusLink. Here’s how ModusLink’s expertise enhances demand-driven strategies:

- Advanced Analytics and Forecasting: ModusLink leverages advanced analytics to develop precise demand forecasts, ensuring optimal inventory levels and efficient resource allocation.

- Inventory Optimization: ModusLink’s inventory management solutions align inventory levels with demand, reducing holding costs and waste.

- Technology Integration: ModusLink integrates cutting-edge technologies such as IoT-enabled tracking and AI-driven analytics, providing real-time visibility into supply chain dynamics.

Benefits of Demand-Driven Planning

Implementing demand-driven material planning with ModusLink offers numerous advantages:

- Cost Savings: Reduced inventory holding costs and minimized waste due to accurate demand forecasts.

- Improved Customer Service: Ensuring packaging material availability aligns with customer demand, reducing delays and stockouts.

- Enhanced Agility: Quick adaptation to changing market conditions and demand patterns.

- Optimized Supply Chain: Streamlined processes and improved efficiency throughout the supply chain.

Conclusion

Demand-driven material planning is a strategic approach that optimizes inventory levels, reduces operational costs, and improves customer satisfaction. By embracing this methodology and partnering with solution providers like ModusLink, businesses can enhance their supply chain resilience and responsiveness. Emphasizing flexibility, data-driven insights, and collaborative relationships is key to succeeding in today’s competitive market environment.

Ready to Elevate Your Material Planning Strategy?

Contact ModusLink today to explore how demand-driven material planning can transform your supply chain and drive business growth. Embrace innovation with ModusLink and unlock the full potential of demand-driven material planning.

Bibliography

OpenAI’S GPT-3 – Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Electronics Kitting and Assembly with 3PL Solutions

Engineer is Holding New HDD Hard Drive. Introduction:

In today’s interconnected world, businesses are seeking agile and cost-effective strategies to meet the demands of an ever-evolving market. By harnessing the capabilities of a global 3PL partner, companies can unlock new possibilities for efficiency, scalability, and innovation in their electronics assembly processes.

- Specialization & Expertise:

- While many companies offer 3PL services, it’s critical to choose a specialized 3PL provider like ModusLink with expertise in handling, storing, and kitting electronic components. Electronics components require specific training, facilities, and equipment due to their delicate nature and sensitivity to environmental factors.

- Consider the unique requirements of your manufacturing process. For high-volume manufacturers, proficiency in efficiently managing large quantities of the same components is essential. Conversely, high-mix manufacturers benefit from partnering with a 3PL specialized in navigating the complexities of handling a diverse range of components.

- Seek a 3PL provider like with a deep understanding of the electronics industry and its specific challenges. Their expertise in electronic component kitting and assembly can streamline your operations and ensure optimal efficiency.

- Additionally, assess the scalability and the demand variability of your business when selecting a 3PL partner. Some 3PLs impose minimum contract size requirements or often minimum / maximum volumes, which may not align with the uncertain needs of a growing business. Choose a partner like ModusLink who can be flexible in accommodating your current needs while also supporting your future growth trajectory.

- Global Reach, Local Expertise:

- Understanding the global footprint of 3PL providers and their local presence.

- Leveraging regional expertise to navigate regulatory requirements and cultural nuances.

- Seamless coordination across borders for streamlined supply chain operations.

- Comprehensive Kitting Services:

- Tailored kitting solutions to meet the unique needs of electronics manufacturers.

- End-to-end management of component procurement, inventory management, and JIT delivery.

- Dynamic inventory optimization to minimize lead times and reduce costs.

- Advanced Assembly Capabilities:

- Access to cutting-edge assembly facilities equipped with state-of-the-art technology.

- Skilled workforce trained in the latest assembly techniques and quality standards.

- Scalable production capacity to accommodate fluctuations in demand.

- Quality Assurance Across Borders:

- Stringent quality control protocols enforced throughout the global supply chain.

- Compliance with international quality standards and regulatory requirements.

- Continuous improvement initiatives driven by data analytics and feedback mechanisms.

- Supply Chain Visibility and Transparency:

- Real-time tracking of components and assemblies across multiple geographies.

- Transparent communication channels for enhanced collaboration and decision-making.

- Predictive analytics to anticipate supply chain disruptions and mitigate risks.

- Cost Efficiency and Value Optimization:

- Economies of scale realized through global procurement and resource pooling.

- Transparent pricing models tailored to meet the budgetary constraints of clients.

- Cost-saving initiatives such as lean manufacturing and waste reduction strategies.

- Innovation and Technology Integration:

- Integration of emerging technologies such as IoT, AI, and robotics in assembly processes.

- Continuous investment in research and development to drive innovation and efficiency.

- Customized solutions leveraging digital platforms for enhanced visibility and control.

- Environmental Sustainability Initiatives:

- Commitment to sustainable practices and ethical sourcing throughout the supply chain.

- Reduction of carbon footprint through energy-efficient operations and green logistics.

- Collaboration with eco-friendly suppliers and adoption of recyclable packaging solutions.

- Case Studies and Success Stories:

- Real-world examples showcasing the transformative impact of global 3PL solutions, including ModusLink.

- Testimonials from satisfied clients highlighting the value proposition of outsourcing assembly operations.

Conclusion:

In an era of rapid globalization and technological advancement, partnering with a global 3PL provider like ModusLink offers unparalleled opportunities for electronics manufacturers to stay ahead of the curve. By leveraging ModusLink’s over 30 years of extensive network and expertise, businesses can optimize their supply chain, drive innovation, and achieve sustainable growth in the dynamic landscape of electronics manufacturing. Embrace the future of assembly with ModusLink and unlock a world of possibilities for your business

Bibliography

OpenAI’S GPT-3

Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

- Specialization & Expertise:

-

Outsourcing eCommerce Fulfillment to a 3PL

Warehouse of wholesale. Logistic, fulfilment order for distribution. Loader, cargo truck, forklift with driver, worker with cart, boxes on rack. Flat illustration for logistic, delivery center. Vector Introduction:

Understanding the Role of a 3PL in eCommerce Fulfillment

Before diving into the benefits of outsourcing, let’s clarify what exactly a 3PL does in the realm of eCommerce fulfillment. A 3PL is a specialized logistics provider that offers a comprehensive suite of services to handle various aspects of the order fulfillment process. From warehousing and inventory management to shipping and returns processing, 3PLs are equipped with the expertise and infrastructure to streamline every step of the fulfillment journey.

The Benefits of Outsourced Fulfillment

Outsourcing fulfillment to a 3PL offers a multitude of benefits that can positively impact your eCommerce business:

- Cost Savings: Building and maintaining an in-house fulfillment operation can be costly and resource-intensive. By leveraging the existing infrastructure and expertise of a 3PL, businesses can significantly reduce operational costs and allocate resources more efficiently.

- Scalability: One of the biggest advantages of working with a 3PL is the ability to scale operations according to fluctuating demand. Whether it’s handling peak holiday seasons or accommodating sudden spikes in orders, 3PLs have the flexibility and resources to scale up or down as needed, without the hassle of investing in additional infrastructure.

- Expertise and Efficiency: Fulfillment is a complex process that requires meticulous attention to detail and efficient execution. 3PLs are staffed with logistics professionals who specialize in optimizing warehouse operations, maximizing inventory accuracy, and ensuring timely order fulfillment. By entrusting these tasks to experts, businesses can streamline their operations and focus on core aspects of their business.

- Expanded Reach: Partnering with a 3PL can open doors to new markets and territories. With strategically located distribution centers and a network of transportation partners, 3PLs enable businesses to reach customers across the globe more efficiently and cost-effectively.

- Customer Satisfaction: In today’s competitive eCommerce landscape, fast and reliable shipping is paramount to customer satisfaction. By outsourcing fulfillment to a 3PL, businesses can offer expedited shipping options, improve order accuracy, and enhance overall customer experience, leading to higher satisfaction and repeat business.

Is Outsourcing Right for Your Business?

While the benefits of outsourcing fulfillment are clear, it’s essential to assess whether it aligns with your business goals and requirements. Consider factors such as your current fulfillment capabilities, growth projections, and budgetary constraints. Ask yourself:

- Are we equipped to handle fulfillment in-house, or would partnering with a 3PL be more efficient?

- Do we anticipate fluctuations in order volume that would necessitate scalable fulfillment solutions?

- What are our long-term growth objectives, and how does outsourcing fit into our strategic roadmap?

- Are we willing to invest in technology and infrastructure, or would it be more cost-effective to leverage the resources of a 3PL?

By carefully evaluating these questions and weighing the benefits of outsourcing, you can make an informed decision that aligns with the needs and aspirations of your eCommerce business.

Conclusion

Outsourcing eCommerce fulfillment to Moduslink offers businesses a strategic advantage in today’s competitive landscape. By leveraging the expertise and resources of a trusted logistics partner like ModusLink, businesses can focus on core aspects of their operations while confidently entrusting their fulfillment needs to capable hands. Whether you’re a small startup or an established enterprise, outsourcing fulfillment to a 3PL can be the key to unlocking greater efficiency, scalability, and success in the competitive world of eCommerce.

Bibliography

Outsourcing eCommerce Fulfillment to a 3PL – Supply Chain 24/7 (supplychain247.com

OpenAI’S GPT-3

Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Global Supply Chain Vulnerability – ModusLink

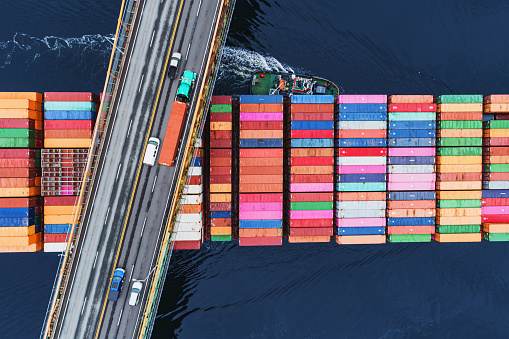

Navigating Troubled Waters: The Red Sea Crisis and the Vulnerability of Global Supply Chains Introduction:

In 2023, approximately 24,000 vessels plied the Red Sea passage, constituting around 10% of global seaborne trade by volume, according to Clarksons, a shipbroker. This includes 20% of the world’s container traffic, nearly 10% of seaborne oil, and 8% of liquefied natural gas. Faced with the challenges posed by the Red Sea crisis, supply chain companies can take proactive measures and enhance the resilience of the global supply chain. By implementing key strategies, they can better navigate troubled waters and ensure the efficient movement of goods across international waters. This update explores essential strategies.

1. Diversification of Shipping Routes:

- Evaluate alternative shipping routes that bypass regions prone to geopolitical tensions or piracy.

- Identify secondary routes for use in case of disruptions in primary routes.

- Collaborate with logistics partners to establish diversified and flexible transportation plans.

2. Investment in Technology:

- Utilize advanced technologies such as blockchain, IoT, and AI for real-time tracking and monitoring of shipments.

- Implement predictive analytics to anticipate potential disruptions.

- Improve communication and information-sharing among supply chain partners through digital platforms.

3. Enhanced Security Measures:

- Collaborate with maritime security agencies and international organizations to ensure the safety of shipping routes.

- Implement security protocols to protect cargo and vessels from piracy and other security threats.

- Invest in surveillance systems and employ security personnel to monitor critical waterways.

4. Risk Assessment and Contingency Planning:

- Conduct thorough risk assessments to identify vulnerabilities in the supply chain.

- Develop comprehensive contingency plans to address potential disruptions and ensure business continuity.

- Regularly review and update contingency plans to adapt to changing geopolitical situations.

5. Supply Chain Visibility:

- Enhance end-to-end visibility across the entire supply chain.

- Collaborate with suppliers and logistics partners to share real-time information on inventory levels, shipments, and potential delays.

- Implement technologies like RFID to track and trace goods throughout the supply chain.

6. Diversification of Suppliers and Manufacturing Locations:

- Avoid overreliance on a single supplier or manufacturing location by diversifying sources

- Assess the geopolitical stability of supplier regions and consider relocating manufacturing facilities if necessary.

- Build strong relationships with suppliers to ensure open communication and collaboration.

7. Collaboration and Industry Partnerships:

- Engage in industry collaborations and partnerships to share best practices and intelligence on potential risks.

- Establish forums for dialogue among supply chain professionals, government agencies, and relevant stakeholders to address common challenges.

- Participate in industry initiatives aimed at improving the overall resilience of global supply chains.

8. Regulatory Compliance:

- Stay informed about and comply with international regulations related to maritime security and trade.

- Regularly update policies and procedures to align with evolving regulatory requirements.

- Collaborate with regulatory authorities to contribute to the development of effective and practical guidelines.

Conclusion

In conclusion, by adopting these strategies, supply chain companies can effectively navigate the troubled waters presented by the Red Sea crisis and enhance the overall resilience of the global supply chain. Proactive planning and a collaborative approach, including leveraging ModusLink’s services, are essential to mitigating risks and ensuring the smooth movement of goods across international waters.

Bibliography

OpenAI’S GPT-3

Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Navigating Seasonal B2B Returns Variability

Global delivery service. Courier holding cardboard box, standing near van. Customer ordering parcel using laptop and sitting on globe. Worldwide shipping, remote flying packages vector Introduction:

In the dynamic landscape of e-commerce, businesses grapple with multifaceted challenges, and chief among them is the management of returns. Whether stemming from customer dissatisfaction, product defects, or changes of mind, returns constitute an inevitable facet of the retail process. Navigating this complex terrain efficiently is pivotal for fostering customer satisfaction and upholding a positive brand image. Enter the indispensable role of outsourcing partners, with industry leaders like ModusLink standing out as transformative forces in optimizing returns management.

Understanding Returns Fluctuations

Returns fluctuations can be intrinsic, exhibiting substantial variability based on product types, customer demographics, and prevailing market trends. During peak seasons or post major sales events, businesses commonly contend with a surge in returns. This surge can strain in-house logistics systems, giving rise to delays, errors, and elevated operational costs.

The Outsourcing Partner Advantage

- Scalability: A pivotal benefit of engaging an outsourcing partner like ModusLink for returns lies in its scalability. During periods of heightened return volumes, ModusLink swiftly scales up operations, negating the need for substantial investments in temporary warehouse space, staff, and technology.

- Expertise: Specializing in logistics and supply chain management, outsourcing partners like ModusLink bring unparalleled expertise to streamline the returns process. From inspecting returned items to restocking or disposing of them, ModusLink handles each step with precision, alleviating the burden on businesses and ensuring compliance with regulations.

- Technology Integration: Modern outsourcing partners, including ModusLink, leverage cutting-edge technologies, including barcode scanning, inventory management systems, and data analytics. These tools facilitate accurate tracking of returned items, real-time visibility into inventory levels, and data-driven insights for optimizing the returns process.

- Cost-Efficiency: Managing returns internally can result in inflated costs, spanning labor, storage, and transportation. Outsourcing returns to partners like ModusLink brings cost savings through economies of scale, shared resources, and streamlined processes, allowing businesses to allocate resources strategically and focus on core competencies.

- Enhanced Customer Experience: Swift and efficient returns processing contributes to a positive customer experience. Outsourcing partners, including ModusLink, expedite refund or exchange processes, enhancing customer satisfaction and loyalty. A seamless returns process can transform a potentially negative experience into a positive one for customers.

The Benefits

The benefits of outsourcing extend beyond traditional cost savings, by delivering value enterprise-wide with renewed focus on the customer and end-user experience.

Conclusion

In the ever-evolving realm of e-commerce, efficient returns management stands as a crucial component for sustaining a competitive edge. The value of employing outsourcing partners like ModusLink for returns fluctuations lies in their capacity to deliver scalable solutions, operational expertise, technology integration, cost-efficiency, and an enriched customer experience. By entrusting the returns process to reliable partners, such as ModusLink, businesses can gracefully navigate the challenges of returns fluctuations, ensuring a smoother and more sustainable supply chain.

Bibliography

OpenAI’S GPT-3

Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Maximize Efficiency and Savings: Discover the Top Benefits of Outsourcing to a 3PL Partner

3PL in Modern Supply Chains Introduction

In the ever-changing realm of modern business, companies continually strive to refine their processes, lower expenditures, and bolster the efficiency of their supply chains. One increasingly popular approach is the delegation of responsibilities to Third-Party Logistics providers, often referred to as 3PLs. These firms provide a diverse array of services for optimizing and overseeing different facets of a company’s supply chain. In this article, we will delve into the key advantages of partnering with 3PLs, with a particular emphasis on the supply chain services offered by ModusLink.

1. Expertise and Specialization:

3PL providers like ModusLink possess extensive expertise and specialization in managing supply chains. They have a dedicated team of professionals who are well-versed in industry best practices, allowing your business to tap into their knowledge and experience. By outsourcing, you can leverage their expertise in areas such as warehousing, transportation, and distribution.

2. Cost Efficiency:

Cost efficiency is a significant advantage of partnering with a 3PL provider. By outsourcing, you can eliminate the need for significant capital investments in infrastructure, technology, and manpower. 3PLs, including ModusLink, already have the necessary resources and technology in place, which can significantly reduce your operational costs and improve your bottom line.

3. Scalability:

One of the key benefits of outsourcing to a 3PL is the ability to scale your operations as needed. Whether your business is experiencing a seasonal surge in demand or facing a downturn, a reputable 3PL like ModusLink can adjust its services to accommodate your specific requirements, helping you maintain operational flexibility.

4. Focus on Core Competencies:

Outsourcing supply chain operations to a 3PL allows your company to focus on its core competencies and strategic initiatives. This can lead to improved product development, marketing, and customer service, while the 3PL handles the logistics and distribution aspects efficiently..

5. Enhanced Technology:

Many 3PL providers, including ModusLink, invest heavily in cutting-edge technology and supply chain management systems. By outsourcing, you gain access to these advanced tools, ensuring greater visibility, transparency, and efficiency in your supply chain operations.

6. Global Reach:

If your business operates on an international scale, partnering with a 3PL like ModusLink with a global network can help streamline your global supply chain management. They have the expertise and infrastructure to navigate international regulations, customs, and shipping, ensuring that your products reach customers worldwide seamlessly.

7. Risk Mitigation:

Supply chain disruptions can be a major headache for businesses. By outsourcing to a 3PL, you can reduce the risk associated with supply chain disruptions, as these providers often have contingency plans and the ability to adapt quickly to unforeseen challenges.

8. Customer Satisfaction:

A well-managed supply chain can directly impact customer satisfaction. Timely and accurate deliveries, easy returns, and transparent tracking systems can lead to happier customers and repeat business.

9. Competitive Advantage

Outsourcing to a 3PL can give your business a competitive edge. You can respond more quickly to market changes, and your overall operations become more agile, allowing you to stay ahead of the competition.

10. Sustainability and Eco-friendliness:

Many 3PL providers, including ModusLink, focus on sustainable and environmentally friendly practices. Outsourcing to such providers can help your business reduce its carbon footprint and contribute to your corporate social responsibility initiatives.

Conclusion:

In conclusion, outsourcing to a 3PL like ModusLink’s supply chain services offers numerous benefits that can significantly enhance your company’s operational efficiency and allow you to focus on your core business and not waste financial, technical and human resources on activities you have little or no control over. Using a 3PL provider allows you to quickly access all the operational logistics and skills needed to carry out certain missions that would have taken you a long time if you had carried them out internally.

The expertise, specialization, and global reach of these providers can make a substantial difference in your supply chain management. By partnering with a trusted 3PL, your business can focus on what it does best while leaving the logistics and supply chain management in the capable hands of experts.

Bibliography

https://www.generixgroup.com/en/blog/3pl-chain-procurement-why-outsourcing

OpenAI’S GPT-3

Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

The Essential Role of 3PL in Modern Supply Chains: Unlocking Success with ModusLink

3PL in Modern Supply Chains Introduction

In today’s rapidly evolving global business landscape, supply chain management has become more complex than ever. Companies face the challenge of meeting customer demands for faster delivery, maintaining cost efficiency, and adapting to ever-changing market dynamics. To address these challenges, many organizations are turning to Third-Party Logistics (3PL) providers. In this blog post, we will explore the pivotal role that 3PL plays in modern supply chains and how partnering with experts like ModusLink can unlock success.

1. Efficient Logistics Management:

3PL providers excel in managing logistics operations. They handle everything from warehousing and transportation to order fulfillment and inventory management, all while optimizing routes, transportation modes, and storage solutions. ModusLink, as a trusted 3PL partner, specializes in efficient logistics management that reduces costs and streamlines operations.

2. Scalability and Flexibility:

The flexibility offered by 3PL services is invaluable during seasonal peaks or market expansions. ModusLink’s scalable solutions allow businesses to adapt quickly to changing demands, ensuring a seamless transition when entering new markets or facing fluctuations in production.

3. Global Reach:

For businesses with international ambitions, ModusLink’s global network of partners and resources facilitates cross-border shipping, customs compliance, and international market penetration. Our 3PL expertise enables businesses to expand globally while ensuring efficient supply chain operations.

4. Technology and Visibility

ModusLink leverages advanced technology solutions to provide real-time visibility into the supply chain. With sophisticated tracking systems, clients can monitor inventory levels, shipment status, and performance metrics, enhancing decision-making and responsiveness to supply chain challenges.

5. Cost Efficiency:

ModusLink’s 3PL services offer cost efficiencies through resource pooling, carrier negotiation, and optimized warehouse space utilization. These savings contribute to improving a company’s bottom line and competitiveness.

6. Focus on Core Competencies:

By partnering with ModusLink, businesses can redirect their focus to core competencies such as product development and customer service, confident that their logistics and supply chain operations are in expert hands.

7. Risk Mitigation:

ModusLink’s 3PL services include robust contingency plans and disaster recovery strategies. In times of supply chain disruption, such as natural disasters or geopolitical events, we help clients mitigate risks and ensure business continuity.

Conclusion:

In the modern business landscape, the role of 3PL providers like ModusLink is pivotal. We serve as strategic partners, helping companies navigate the complexities of supply chain management, reduce costs, and enhance efficiency. Third-party logistics providers make all their services possible by mapping out a supply chain network and collaborating with experts to ensure your products/services reach their intended destinations efficiently and cost-effectively. Whether you’re a small startup or a multinational corporation, partnering with ModusLink can unlock success in your quest for an optimized supply chain and sustainable growth. Consider harnessing the power of 3PL to elevate your supply chain operations, and contact ModusLink today to explore how our services can benefit your business.

Bibliography

https://www.supplychainwarehouses.com/post/3pl-explained

OpenAI’S GPT-3

Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Inventory Management Best Practices for Tech Companies: Knowledgeable Insights by ModusLink

Inventory Management Introduction:

In the rapidly evolving tech industry, maintaining optimal inventory management practices is crucial for sustained growth and competitiveness. This blog delves into industry-leading inventory management best practices.

Distinguishing Inventory Management from Supply Chain Management:

While inventory management and supply chain management are closely related, it’s important to recognize that these terms are not interchangeable. They represent distinct facets of the broader logistics and operations landscape.

Supply Chain Management:

Supply chain management takes on a comprehensive role in overseeing the entire journey of products, from their origin as raw materials or components through the stages of production, sourcing, and ultimately, final distribution to end customers. It encompasses the strategic planning and coordination of activities that drive the flow of goods and information across the entire supply chain network. This includes optimizing processes, managing supplier relationships, and ensuring timely and efficient delivery to meet customer demand.

Inventory Management:

Conversely, inventory management focuses specifically on the products a business holds within its operations. It involves receiving, tracking, and efficiently storing these products. Beyond physical control, inventory management provides essential data and insights that enable informed decision-making in areas such as procurement and stock replenishment. It plays a vital role in maintaining the right quantity of products on hand to meet customer demands while avoiding overstocking or stockouts.

Supply chain management encompasses the entire product journey, while inventory management hones in on the precise control and data-driven aspects of the products a business maintains.

1. Demand Forecasting and Predictive Analytics:

Leveraging advanced demand forecasting and predictive analytics tools empowers large tech companies to anticipate market trends and demand fluctuations accurately. A data-driven approach ensures that inventory levels are optimized, reducing excess stock and minimizing the risk of stock outs.

2. Dynamic ABC Analysis:

Introducing a dynamic ABC analysis strategy that categorizes inventory items based on both value and demand volatility allows large tech companies to align their inventory management strategies with changing market dynamics, resulting in optimized stock levels and efficient resource allocation.

3. JIT Inventory Excellence:

Just-in-Time (JIT) inventory management methodology, backed by robust supplier relationships, helps large tech companies achieve operational excellence. Seamless coordination with suppliers enables on-time deliveries and efficient production processes while minimizing carrying costs.

4. Real-time Inventory Visibility with Advanced Technology:

Cutting-edge inventory management technology provides real-time visibility into inventory levels across multiple locations. These solutions offer large tech companies the tools to monitor stock movement, track trends, and make data-driven decisions, ensuring optimal stock allocation and avoiding disruptions.

5. Collaborative Supplier Partnerships:

Recognizing the significance of supplier collaboration, these strategies foster strong partnerships, allowing large tech companies to achieve faster lead times, accurate order fulfillment, and cost-effective procurement. Together, they ensure a responsive supply chain that adapts to changing demand. Managed services can help continually evolve business functions to keep up with ever-changing targets while hitting key stops along the way.

6. Strategic Safety Stock Management:

Strategic safety stock management methodologies tailored to the tech industry’s dynamic nature involve analyzing demand variability and market trends to assist large tech companies in maintaining optimal safety stock levels, balancing customer satisfaction and cost-efficiency.

7. Technology Integration and Process Automation:

Seamless integration of inventory management technologies enhances accuracy and efficiency. These solutions incorporate automated tracking systems, barcode scanners, and RFID technology to minimize errors, optimize order picking, and streamline warehouse operations.

8. Continuous Improvement and Performance Metrics:

Large tech companies benefit from continuous improvement initiatives driven by performance metrics. Analyzing inventory turnover ratios, stock accuracy, and fill rates ensures that inventory management strategies stay aligned with business goals.

Conclusion:

These expertise-driven practices can benefit your business and elevate your inventory management practices. When customers use ModusLink to manage their inventory, we have robust processes in place to ensure world-class inventory management as part of our VMI service. If you’re in search of logistics support, we’re here to assist you.

Bibliography

https://advisory.kpmg.us/services/kpmg-managed-services.html

OpenAI’S GPT-3

Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

A Long Road Ahead for Procurement Professionals Managing Their Supply Chains

Supply Chain Management In the ever-evolving world of freight and logistics, volatility has become the new normal. Procurement experts face transportation costs, customer demands, and high pressure on global container and air freight rates.

Any logistics provider will be well aware of these issues, but it’s possible to overlook how much things have changed in recent years.

Consider global container shipping rates.

Container rates in late July 2023 reached $1323 per TEU, significantly surpassing the late-2019 rates of $1236.87 before the COVID lockdown (Freightos).

Ocean shipping rates will remain high and unpredictable until the end of 2023, compared to pre-pandemic years, so shippers need to adjust and find new ways to succeed. Supply chain optimization software can help companies navigate challenges, streamline operations, and achieve sustainable success. But what does that mean for future strategies in procurement?

Let’s consider the challenges and define a few strategies to help. Let’s think back on demand forecasting and warehousing management. Let’s rethink everything to figure out what it might be for the future of procurement in light of it all.

The Challenges of Freight Procurement for Today’s Shippers

Understanding and addressing the unique challenges of today is the first step in crafting a future-proof procurement strategy. The shifting dynamics between carriers and shippers and frequent disruptions have made it increasingly difficult for shippers to navigate the market.

Ongoing Optimization

Shippers must optimize their procurement strategies. Handling mini-bids, for example, can be challenging for companies operating with limited data and analytics. The lack of real-time market insights can hinder shippers’ ability to make informed decisions and seize opportunities.

Advanced Technologies

The growth of e-commerce has led to increased demand for advanced technologies and functions. However, identifying the right technologies, implementing them, and training staff takes time and effort. Shippers must also contend with the complexities of integrating new technologies into their existing systems.

Quick Responsiveness

Volatility means shippers must recover from disruptions quickly and apply lessons learned faster. Achieving this level of agility in fulfillment and manufacturing requires robust processes, effective communication, and a supportive culture. Shippers must be prepared to pivot their strategies in response to market changes and external factors.

Proactive Risk Mitigation

Companies should prioritize risk management and mitigation, but developing and implementing mitigation strategies can be complex and challenging. Shippers must assess potential risks across their supply chains, from factory to final mile delivery, and implement mitigation measures.

CO2 Emissions Regulations

As McKinsey & Company highlighted, emissions and new regulations will inevitably impact supply chain procurement processes (Kaiser et al.). Shippers must stay informed about regulatory changes, assess their impact, and make necessary adjustments. This requires a proactive approach to compliance and a commitment to sustainability.

How to Approach and Overcome the Procurement Issues

To navigate the volatile freight and logistics industry successfully, shippers must employ targeted strategies that are proactive, agile, and data-driven. Here are some key strategies, along with more detailed explanations:

Automate Optimization

Shippers can leverage data analytics and market intelligence tools–core functions at ModusLink–to automate the initiation of optimization efforts. Shippers can make more informed decisions and capitalize on emerging opportunities by harnessing real-time market insights. Predictive analytics can also anticipate market trends and proactively adjust procurement strategies. This approach allows shippers to stay ahead of the curve and respond effectively to changing market conditions.

Adopt Advanced Technologies

The adoption of advanced technologies is crucial for supporting e-commerce logistics and fulfillment. Shippers should invest in technologies that enhance supply chain visibility, automation, and efficiency. Integrating technologies related to transportation services and understanding shipping costs can be instrumental in streamlining operations.

Logistics providers know these issues but may need to realize how much things have changed lately. Choosing a logistics provider that applies and offers advanced technologies can streamline this process too. Of course, there are some risks to consider.

It’s important to carefully select technologies that comply with the company’s specific needs and implement robust integration strategies. This approach can help shippers improve customer service, gain a competitive edge, and effectively manage inventory management.

Pursue Proactive Risk Mitigation

Shippers must find and deal with possible risks in their supply chains, from the factory to the final delivery. They should assess and reduce threats to minimize the impact of problems. Shippers can ensure they receive good service and value from their logistics partners by making suppliers accountable for meeting goals. This helps strengthen the supply chain, allowing shippers to handle a changing market better.

Visualize Network Optimization

Shippers can use data visualization tools to improve their supply chain performance and reduce costs. They should also evaluate their suppliers to ensure they meet goals and provide good service. This helps build strong relationships and optimize supply chain operations.

Core Benefits of AddressThose

Addressing shippers’ challenges means retooling communication and execution processes to do more with less (Keelvar). That may include using advanced technologies, proactive risk mitigation strategies, and supply chain optimization software or services. Those impacts will help shippers ensure compliance, foster transparency, react to market changes, and achieve sustainable success.

Create a Better Supply Chain Management Plan With ModusLink

Logistics disruptions are bound to happen, but the right partner can help you change how your organization deals with them. Planning and optimizing your supply chain to handle these disruptions effectively is essential. Procurement should adapt to the market and manage inventory levels, reducing them strategically when necessary. Luckily, partnering with ModusLink can help your organization achieve these goals. Contact a team member today to begin.

Works Cited

Freightos. Freightos Terminal – Global Air and Ocean Market Intelligence, https://app.terminal.freightos.com/fbx. Accessed 16 August 2023.

Kaiser, Felix, et al. “Managing supply chain risks.” McKinsey, 19 May 2022, https://www.mckinsey.com/industries/chemicals/our-insights/procurement-early-warning-systems-and-the-next-disruption. Accessed 1 August 2023.

Keelvar. “Strategies for Sourcing Excellence in a Volatile Supply Chain Market.” Keelvar, https://www.keelvar.com/documents/strategies-for-sourcing-excellence-in-a-volatile-supply-chain-market. Accessed 28 July 2023.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

The German Supply Chain Law Effects on Global Trade and Compliance

German Supply Chain Law Global trade is essential today as it allows countries to specialize in producing goods and services that they are most efficient at while enabling them to access a broader range of products worldwide. This leads to higher efficiency, lower costs, improved digitalization and automation, and more significant innovation. Ultimately, this benefits both producers and consumers as supply chain optimization depends on smooth global relationships and trade. Still, the future of omnichannel supply chain optimization is changing to reflect a growing consensus around the importance of tracking data and keeping everything fair. This is on full display with the German Supply Chain Due Diligence Act now in effect, as shared by IBM (German Supply Chain Due Diligence Act (SCDDA) explained). Let’s take a closer look at the implications of the law and how it’ll impact global trade and compliance.

Overview of the German Supply Chain Law

Global supply chains face mounting challenges on multiple fronts, especially with omnichannel 3PL services, network management, and operation. The convergence of geopolitical events, the Covid pandemic, and natural disasters have conspired to disrupt supply chains globally. In addition to these external pressures, companies must contend with an increasing number of legal requirements for supply chain management.

This represents a notable shift in the omnichannel supply chain landscape, with more countries moving away from voluntary measures and self-commitments towards mandatory regulations. Several countries have taken concrete steps in this direction, and this newest piece of legislation’s impacts can only be explained by breaking down the facts of how they’ll impact companies operating in or with Germany.

The German Supply Chain Law entails due diligence obligations relating to human rights and environmental risks and violations. It impacts traditional import and export relationships and e-commerce in the EU. Improving supply chain operations, managing transportation costs and profits, and ensuring safe and ethical operations is the primary goal of this new law. As explained by Global Supply Chain Compliance, these can include the following (Thoms and Fischer).

- Prohibition of known child labor and unsafe employment of minors.

- Prohibition of work of those believed to be trafficked and slaves.

- Prohibition of all forms of oppression within manpower.

- Prohibition of non-compliance with labor protection obligations.

- Prohibition of discrimination in supply chain optimization.

- Prohibition of withholding pay or failure to provide adequate wages.

- Prohibition of efforts to deny the right to form trade unions.

- Prohibition of attempts to block human rights and environmental protections.

- Prohibition of torture, manipulation, and unsafe conditions.

- Prohibition of mercury use, production, raw materials, and waste handling.

- Prohibition of production and use of chemicals under certain restrictions.

- Prohibition of hazardous waste imports and exports in some situations.

- Prohibition of unethical omnichannel supply chain practices.

Global fulfillment, shipping, and transportation companies focused on customer demands and order fulfillment rely on multiple channels to maximize the opportunities global import and export trade allows. E-commerce fulfillment, omnichannel 3PL services, 3PL partnerships, retail and wholesale relations, and supply chain integration are all impacted by the German Supply Chain Ruling.

The German Supply Chain Law obliges companies to observe the human right and environmental due diligence obligations in their supply chain appropriately. The due diligence obligations covered for global trade with German businesses include a range of points that touch on everything from e-commerce challenges, e-commerce fulfillment, omnichannel supply and omnichannel fulfillment, and supply chain management:

- The establishment of an integrated end-to-end risk management process.

- The internal designation of duties and responsibilities with hiring practices.

- The performance of routine and in-depth risk analyses and responses.

- The adoption and enforcement of human rights policies and protections.

- The enforcement of ethical practices focused on forecast demand and budgeting.

- The establishment of preventive measures for direct and indirect suppliers.

- Taking remedial action in the event of a violation of a protected legal position.

- The establishment of complaints procedures for omnichannel supply chains.

- The implementation of due diligence measures regarding risks at indirect suppliers.

- The documentation and reporting of the required paperwork to the authorities.

- The use of ethical practices involving supply chain optimization and monitoring.

Compliance Challenges and Strategies for Importing and Exporting Companies

A central aspect of the legal framework is the requirement for companies to implement measures within their own business operations and in relation to their direct suppliers. In some instances, such as when there are indications of violations, companies may even be obligated to take action concerning their indirect suppliers. This effectively extends the scope of responsibility of companies beyond their primary operations and into their supply chain.

However, it’s important to note that these obligations are generally framed as duties of effort, meaning that not every infringement of human or environmental rights will automatically be considered a violation of the German Supply Chain Law. Instead, companies must demonstrate that they have taken appropriate measures and done everything reasonably possible to prevent such violations from occurring within their supply chain.

The Outlook For Companies Impacted by the Law

As of January 1, 2023, the German Supply Chain Law took effect and significantly impacted businesses operating in Germany. The law will apply to all companies, regardless of their legal structure, that have a head office, principal place of business, administrative headquarters, or branch office located within Germany. This means many aspects of global trade networks and partnerships will be impacted.

Initially, the law will only be enforced on companies with a minimum of 3,000 employees. However, starting from January 1, 2024, the scope of the law will be expanded to include companies that employ at least 1,000 employees, and based on the business register of the Federal Statistical Office, this criteria will apply to nearly 3,000 companies in Germany. The determination of the number of employees can be challenging, particularly in the case of affiliated group structures. Omnichannel supply chain, e-commerce, and other supply chain logistical challenges will be brought front and center with implementing these new laws and regulations.

Stay in Compliance With the German Supply Chain Act With ModusLink.

Global supply chains face increasing pressure from various sources, including geopolitical events, natural disasters, supply chain optimization challenges, and the COVID-19 pandemic. Additionally, there is a trend towards mandatory regulations rather than voluntary measures and self-commitments. Countries such as the UK, France, and Germany are introducing laws related to supply chain and supply challenges management.

The 2023 effects are already being felt as the first wave of German Supply Chain Laws roll out, and more changes will come when the 2024 laws take effect. Contact ModusLink today to learn more about supply chain compliance, improved supply chain, enhanced inventory management, and better international trade relationships with Germany and other EU countries.

Bibliography

“German Supply Chain Due Diligence Act (SCDDA) explained.” IBM, https://www.ibm.com/blog/german-supply-chain-due-diligence-act-scdda-explained/. Accessed 11 March 2023.

Thoms, Anahita, and Kimberley Fischer. “New German Supply Chain Due Diligence Act: The early bird catches the worm.” Global Supply Chain Compliance, 4 November 2022, https://supplychaincompliance.bakermckenzie.com/2022/11/04/new-german-supply-chain-due-diligence-act-the-early-bird-catches-the-worm/. Accessed 11 March 2023.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

.