-

The Subscription Economy in 2026: Why 3PLs Are Now the Backbone of Recurring Revenue

Happy woman opening a package at home after shopping online – e-commerce concepts As subscription models mature, brands across industries—from consumer electronics and health & beauty to retail, MedTech, industrial, and software—are shifting from one‑time transactions to recurring revenue strategies that prioritize customer lifetime value. But behind every renewal, upgrade, and replenishment cycle lies a critical operational reality:

Subscriptions only scale when supply chains do.

Digital subscription complexity—billing cycles, consumption tracking, plan changes—has a physical counterpart requiring precision and consistency. For today’s leading subscription brands, this makes logistics and fulfillment central to the business model.

Why Logistics Has Become a Core Subscription Capability

- Smaller, more frequent shipments

- Real‑time inventory visibility

- Dynamic SKU and bundle variations

- Automated replenishment

- Last‑mile reliability

- Efficient returns and refurbishment

Whether it’s tech accessories, beauty replenishment programs, retail membership bundles, MedTech device rotations, or industrial parts subscriptions—subscriptions are living, evolving entities. Their supporting supply chains must operate with the same flexibility.

The Operational Reality: The Subscription Fulfillment Iceberg

Much like the “billing iceberg,” logistics has its own hidden layers of complexity:

- Forecasting tied to churn and seasonal behavior

- Multi‑node inventory routing

- Automated reorder points and cycle‑based workflows

- Carrier performance optimization

- Exception management for recurring orders

- Packaging consistency and sustainability requirements

- Reverse logistics and refurbishment cycles

Across sectors like consumer electronics, MedTech, health & beauty, and retail, ModusLink helps brands streamline this complexity by combining automation, analytics, and global fulfillment capabilities—all engineered for recurring operations.

How 3PL Agility Drives Subscription Success

1. Predictive Inventory for Recurring Demand

Subscription cycles create predictable data patterns, that requires subscription‑specific modeling to support:

- Renewal forecasting

- Upsell and add‑on trends

- Promotional volume shifts

- Payment‑failure fallout

This is especially valuable for inventory‑sensitive industries such as electronics, MedTech devices, and consumables.

The result: right‑sized inventory, healthier cash flow, and improved order accuracy.2. Automated, Modular Fulfillment Workflows

Today’s subscription brands use hybrid models—usage‑based, replenishment, or tiered plans. This applies across:

- Consumer electronics (accessories, upgrades)

- Health & beauty (replenishment cycles)

- MedTech (refurbish/replace programs)

- Retail (membership & curated boxes)

- “Replenish when low” triggers

- Variable order quantities

- Rolling fulfillment tied to billing cycles

- Plan‑dependent packaging and inserts

Workflows stay consistent even as customer behavior and product lifecycles shift.

3. Last‑Mile Experience Drives Retention

In recurring commerce, the delivery experience is the product.

- Diversified carrier strategies

- Delivery analytics and proactive alerts

- SLA monitoring and performance tuning

- Lower damage and delay rates

For industries like beauty, consumer tech, and retail—where customer satisfaction drives membership retention—better delivery performance directly reduces churn.

4. Reverse Logistics Purpose‑Built for Subscriptions

Trials, swaps, and upgrade paths demand fast, clean reverse logistics—especially in MedTech, consumer electronics, and industrial sectors.

- Automated RMAs

- Refurbishment and resale loops

- Condition‑based disposition

- Data insights to support retention strategies

Reverse logistics becomes a value driver, not an operational burden.

Build vs. Buy: Why 3PLs Accelerate Subscription Growth

Building an internal subscription‑ready supply chain requires:

- Warehouses

- Automation investments

- Staffing models

- Carrier contracts

- Returns infrastructure

For most subscription brands—whether in electronics, beauty, MedTech, retail, or industrial markets—this approach slows growth.

- Faster onboarding

- Lower operating costs

- Automation and robotics already in place

- A scalable global footprint

- Integrated visibility across nodes

- Optimized carrier networks

In today’s Subscription Economy, 3PLs aren’t cost centers—they’re strategic enablers of recurring revenue.

Recurring revenue requires recurring fulfillment performance.

Brands that partner with agile, data‑driven 3PLs like ModusLink will lead the next phase of subscription growth in 2026 and beyond. reduce costs, recover value, and deliver exceptional customer experiences while meeting sustainability objectives.👉 Contact ModusLink today to discover how we can help you design flexible, resilient, and future-proof supply chain solutions tailored to your business.

Bibliography

Sources:

This blog incorporates insights informed by Baytech Consulting’s publication, “Unlocking Recurring Revenue: The Subscription Economy in 2026,” released January 12, 2026.

Microsoft 365 -Copilot

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

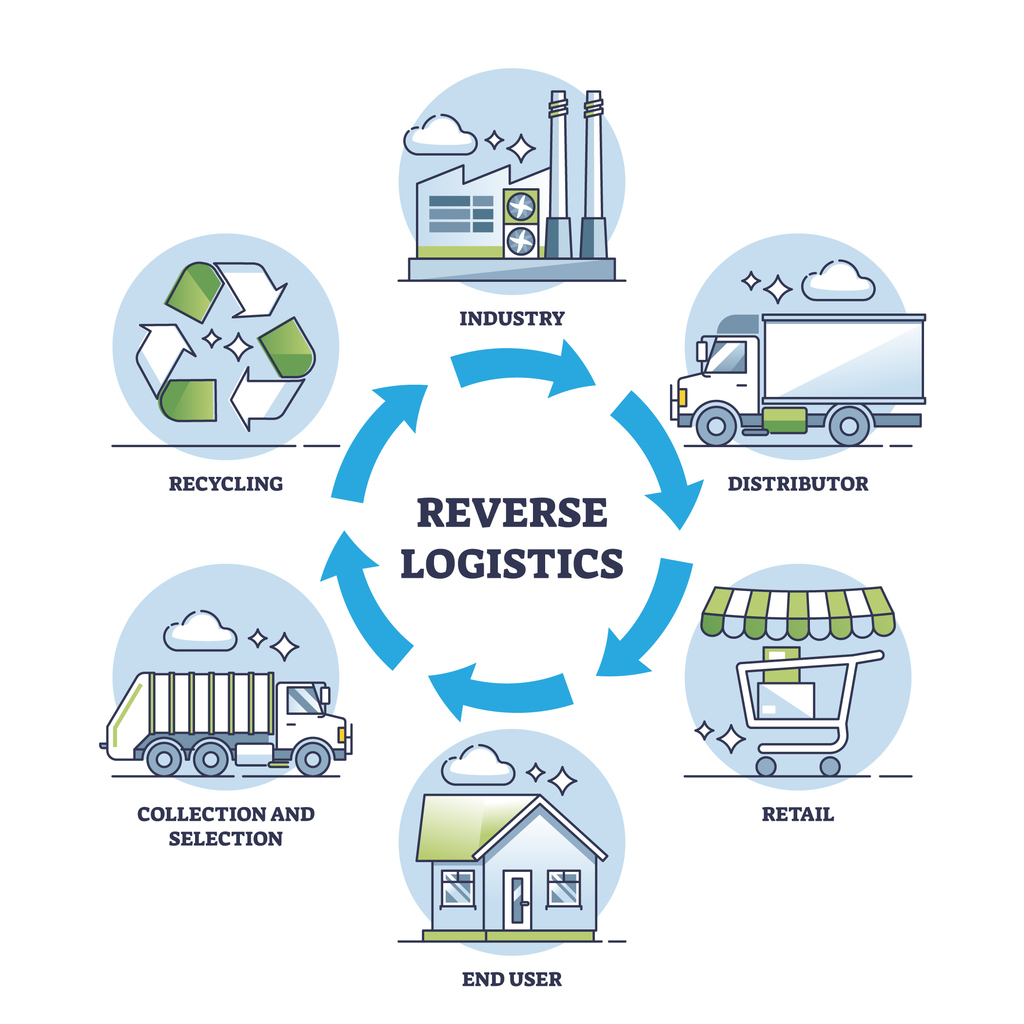

Reverse Logistics Market Outlook 2026-2034

Reverse logistics as green supply chain management type outline diagram. Labeled educational scheme with sustainable product cycle and packages return for recycling and reusage vector illustration. The Reverse Logistics Market is valued at USD 860.4 billion in 2025 and is projected to grow at a CAGR of 9.8% to reach USD 1.99 trillion by 2034. The market is being reshaped by the surge in online purchases and try-before-you-buy models, rising sustainability commitments, and extended producer responsibility frameworks that push closed-loop flows. This evolution is redefining how businesses manage returns, refurbishments, and recommerce, turning what was once a cost burden into a strategic advantage.

Key Growth Drivers

Expanding Recommerce Channels

Recommerce is becoming mainstream as brands embrace resale platforms and marketplace partnerships to monetize returns. This shift not only reduces waste but also creates new revenue streams. By refurbishing and reselling returned products, companies can extend product lifecycles and support circular economy initiativesAI-Driven Disposition Decisioning

Artificial intelligence is revolutionizing reverse logistics by enabling intelligent disposition decisions. Advanced systems now determine whether returned items should be refunded, repaired, refurbished, or recycled—optimizing recovery rates and reducing unnecessary touchpoints. This capability reduces operational complexity and accelerates turnaround times, which is critical in high-volume e-commerce environments.Automation for Efficiency

Automation is no longer optional—it’s essential. Vision-based grading, automated bagging, and robotics are accelerating throughput and reducing labor variability. These technologies ensure consistency and scalability in handling high return volumes, while reducing human error and improving cost efficiency.Emerging Trends

Sustainability as a Differentiator

Environmental responsibility is now a key factor in provider selection. Practices like landfill diversion, carbon-aware routing, and recycled packaging are shaping competitive advantage. Brands are increasingly prioritizing partners that can help them meet ESG goals while maintaining operational efficiency.Omnichannel Returns

Consumers expect convenience. Box-free drop-off, parcel lockers, and dynamic return policies enhance customer experience while mitigating fraud risk. Retailers and logistics providers are investing in technology-driven solutions to deliver seamless omnichannel experiences that balance flexibility with security.Hazmat & Battery Complexity

The rise of electric vehicles and regulated goods introduces new compliance challenges. Specialized handling for EV batteries and hazardous materials is critical for safety and regulatory adherence. Providers must invest in certified processes and infrastructure to manage these complexities effectively.Regional Insights

- North America: High e-commerce penetration drives box-free returns and near-market refurbishment.

- Europe: Strict producer responsibility rules push repairability and recycling, especially for electronics.

- Asia-Pacific: Fragmented flows demand localized repair clusters and automated grading.

- Middle East & Africa: Infrastructure development focuses on parcel lockers and bonded facilities.

- South & Central America: In-region refurbishment and regulatory clarity on e-waste are key priorities.

These regional dynamics highlight the need for global providers to offer localized solutions that meet compliance requirements and consumer expectations.

Why It Matters

Reverse logistics is no longer a cost center—it’s a strategic lever for margin improvement, customer loyalty, and sustainability goals. Companies that embrace AI, automation, and circularity will lead in this $1.99 trillion market.

ModusLink is uniquely positioned to help brands succeed in this evolving landscape. With end-to-end reverse logistics solutions—including intelligent returns management, automated processing, recommerce enablement, sustainable packaging, and global fulfillment—ModusLink transforms returns into a competitive advantage. By combining advanced technology, global infrastructure, and ESG-driven practices, ModusLink empowers businesses to reduce costs, recover value, and deliver exceptional customer experiences while meeting sustainability objectives.

👉 Contact ModusLink today to discover how we can help you design flexible, resilient, and future-proof supply chain solutions tailored to your business.

Bibliography

Sources:

This blog is based on insights from Research and Markets’ report: “Reverse Logistics Market Outlook 2026-2034: Market Share, and Growth Analysis” (November 13, 2025). For the full report, visit Research and Markets.

👉 Contact ModusLink today to discover how we can help you design flexible, resilient, and future-proof supply chain solutions tailored to your business.

Microsoft 365 -Copilot

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

The Strategic Backbone of Personalized Fulfillment

Cardboard boxes on moving belt conveyor at distribution warehouse. Modern warehouse with automatic moving conveyor machine. In the fast-paced world of e-commerce and manufacturing, customer expectations have reached a fever pitch. Shoppers don’t just want a product; they want their product—bundled with specific accessories, curated for their taste, and shipped immediately. The era of the generic, mass-market product is fading.

This shift to hyper-customization and personalization is forcing supply chains to evolve, and the quiet powerhouse making it all possible is state demand kitting—a dynamic, data-driven approach to late-stage product configuration. Kitting is no longer a simple logistics task; it’s a strategic differentiator that enables businesses to deliver a ‘just-for-me’ experience without sacrificing efficiency. Companies like ModusLink have built their global supply chain services around this principle, using kitting as the core tool for agile, responsive fulfillment.

The Rise of On-Demand Customization

Traditional kitting involved batching—pre-assembling thousands of identical kits months in advance. Today, that model is being replaced or supplemented by state demand kitting, where the final product or bundle is assembled after the customer’s order is placed. This is often referred to as postponement—delaying the final configuration until the last possible moment to align with real-time demand signals.

Application The Customization Challenge Kitting Solution (The ModusLink Approach) Subscription Boxes Users demand unique, hand-picked monthly items based on their profile (e.g., color, size, dietary preference). Kitting allows for dynamic assembly, pulling components based on real-time customer data just before shipping, making every box unique and highly relevant. E-commerce Bundles Offering promotional bundles, “build-your-own” product configurations, or a special gift-with-purchase (GWP) that changes weekly. Kitting enables flexible product creation, consolidating various SKUs (like a phone, case, and charger) into one single package for a seamless fulfillment process, often in-region to reduce lead times. Manufacturing Building products with numerous optional features (e.g., custom color trim on a machine or specific software pre-loaded). Services like those provided by ModusLink manage content loading (like firmware flashing on a device) and assembly at the point closest to the customer, ensuring the product is complete and customized upon delivery. By moving the final assembly step closer to the time of order, state demand kitting becomes the agile bridge between mass production and individual consumer demand.

Reduced Inventory Risk: The Power of Postponement

One of the most powerful benefits of state demand kitting is the dramatic improvement in inventory management.

Instead of tying up capital and warehouse space in thousands of pre-assembled finished goods, companies store individual, generic components. This practice offers two critical advantages:

- Reduced Obsolescence: If a trend changes or a product version is updated, a company is left with raw components that can be used for other kits or products, rather than thousands of outdated, pre-assembled items. This is key to enhancing adaptability and reducing excess and obsolete (E&O) inventory risk, a significant financial benefit highlighted in numerous supply chain case studies.

- Lower Carrying Costs: Storing fewer finished products and more raw material lowers inventory holding costs (storage, insurance, obsolescence risk). When an order hits the system, the necessary components are pulled, assembled, and shipped—a lean, efficient process that directly translates to lower overall logistics costs.

The Digital and Data-Driven Warehouse Ensures Accuracy 📊

Customization at scale is impossible without flawless execution. This is where modern digital and data-driven warehouse technology steps in to ensure every personalized kit is perfect.

- Real-Time Traceability for Quality: Utilizing robust systems like Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP), kitting operations can track every component from the supplier to the final assembly. This enhanced visibility is essential not only for compliance and quality control but also for rapid troubleshooting. A good global solution will provide a single view of the supply chain, which is critical when components are sourced internationally but assembled locally.

- Automation and Scanning for Precision: Advanced fulfillment centers leverage automation and integrated scanning technology to guarantee accuracy. This includes barcode/RFID application and automated checking systems that validate every component is correctly picked and assembled according to the Bill of Materials (BOM). This focus on systematic controls and integrated data ensures that human error is virtually eliminated in the high-volume kitting process.

- Single-SKU Simplification: Despite having a thousand possible combinations, the final kit is tracked under one single Kit SKU. This administrative simplification is a game-changer, dramatically streamlining tracking, purchasing, and order fulfillment. This reduction in the number of active SKUs being managed by fulfillment teams leads to fewer errors and faster processing times for the end customer.

The Bottom Line: Efficiency and Experience

The current kitting and assembly trends are all converging on two key outcomes: unprecedented operational efficiency and an improved customer experience. By mastering the art of late-stage configuration, supply chain service providers enable companies to meet the demanding consumer desire for a highly personal product, all while maintaining lean inventory and a resilient global structure. The future of logistics is personal, and kitting is the mechanism that delivers it.The future is uncertain—but your supply chain doesn’t have to be.

👉 Contact ModusLink today to discover how we can help you design flexible, resilient, and future-proof supply chain solutions tailored to your business.

Bibliography

Sources:

Gemini – M365-Copilot Information was also provide

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Global Supply Chains in 2025: From Disruption to Realignment

2025 goals with Business development concepts. Global supply chains are undergoing seismic shifts. Disruptions are no longer temporary—they represent a structural realignment. From semiconductor transitions to changing consumer demand patterns, companies must act decisively to remain competitive.

At ModusLink, we believe this is not a time for reactive measures. It’s a time to re-engineer supply chains for resilience, agility, and long-term growth.

Semiconductor Transformation: Managing the Shift

Semiconductor manufacturing is entering a new era as legacy processes are phased out and advanced technologies rise to dominance. For companies dependent on older components, this transition poses serious supply continuity risks.

🔹 ModusLink Advantage: We can help clients manage transitions through supplier diversification, global sourcing, and phased migration strategies. Our end-to-end solutions minimize disruption while ensuring production stays on track.

AI Infrastructure: A New Growth Engine

For the first time, AI servers are surpassing smart electronics in revenue growth. Data center accelerators are projected to hit $446 billion by 2029. (Converge Digest, 2025)

🔹 ModusLink Advantage: We specialize in logistics for high-value, complex technology products. From secure warehousing and global distribution to real-time inventory optimization, we enable businesses to keep pace with fast-evolving market demand.

Beyond Efficiency: Building Resilient Supply Chains

The global supply chain landscape has outgrown efficiency-only models. The future belongs to companies that prioritize resilience, adaptability, and foresight.

🔹 ModusLink Advantage:

- Regionalized networks to reduce dependency on single geographies.

- Digital visibility tools for proactive decision-making.

- Risk-mitigation strategies that safeguard operations against disruption.

Automotive & Electronics: A New Convergence

The EV and electronics industries are increasingly intertwined, facing tariffs, labor challenges, and software integration pressures.

🔹 ModusLink Advantage: We can support OEMs and Tier 1 suppliers with specialized EV logistics, compliance management, and circular supply chain solutions—helping clients reduce costs while meeting sustainability goals.

Pricing Flexibility: Aligned With Customer Needs

Every business defines cost structures differently. Some prefer one global price for simplicity, while others require region-specific pricing for market alignment.

🔹 ModusLink Advantage

We provide pricing models that adapt to our clients’ business strategies—ensuring transparency, predictability, and alignment with financial objectives across diverse geographies.Technology: Intelligence Driving Operations

Digital assets are only the beginning. The next frontier is the use of AI-driven intelligence across every operational layer—inventory, shipping methods, and warehouse optimization.

🔹 ModusLink Advantage

- Expanding AI Capabilities in Supply Chain Services – Actively investing in advanced AI solutions to strengthen resilience, efficiency, and client value.

Why ModusLink?

Today’s supply chains are being rewritten. Companies that succeed will be those who:

✔️ Diversify globally

✔️ Embrace digital intelligence

✔️ Prioritize resilience over efficiency

✔️ Align pricing models with regional and global business needs

✔️ Harness AI to optimize inventory, shipping, and warehouse operationsThat’s where ModusLink comes in. With decades of expertise, a global footprint, and a relentless focus on innovation, we enable businesses to:

- Future-proof supply chains against disruption.

- Adapt cost structures with flexible global or regional pricing.

- Leverage advanced AI technologies for smarter, faster, and more efficient operations

Ready to Build a Resilient Supply Chain?

The future is uncertain—but your supply chain doesn’t have to be.

👉 Contact ModusLink today to discover how we can help you design flexible, resilient, and future-proof supply chain solutions tailored to your business.

Bibliography

Sources:

OpenAI’S GPT-3 – Information was also provided by OpenAI’S GPT-3 language model.

Rand Technology, “Global Supply Chain – August 2025,” published July 20, 2025 and Converge Digest.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Peak season is coming fast. The e-commerce world isn’t waiting—and neither should you

US Global Trade War, as American tariffs with opposing cargo freight containers in conflict as an economic dispute over import and exports. As we edge closer to Q4 2025, the air for e-commerce businesses isn’t just getting colder; it’s getting electrified with the promise of peak season sales. For brands with global aspirations, the stakes are even higher. While the rewards of tapping into international markets are immense, the complexities of cross-border e-commerce can quickly turn opportunity into logistical nightmares.

At ModusLink, we know that success in the global marketplace isn’t just about having great products – it’s about having a seamlessly integrated supply chain that can deliver them efficiently, compliantly, and profitably, no matter the destination.

So, how can your brand master cross-border e-commerce for a truly triumphant Q4 2025? Let’s dive in.

The Q4 Cross-Border Gauntlet: Key Challenges

Peak season amplifies every supply chain challenge. For international shipments, these become critical roadblocks:

- Tariff Turmoil & Customs Delays: As highlighted in our recent blogs, global trade policies, including tariffs and import duties, remain dynamic. Navigating these, alongside stringent customs regulations, can cause significant delays and unexpected costs.

- Fluctuating Shipping Costs & Capacity: Demand surges during Q4, driving up freight costs and tightening carrier capacity. Securing reliable and cost-effective shipping lanes is paramount.

- Local Payment & Currency Management: Offering local payment methods is crucial for conversion, but managing multiple currencies, foreign exchange rates, and international payment gateways adds complexity.

- Returns Management Headaches: International returns are notoriously difficult and expensive. A smooth process is vital for customer satisfaction but often overlooked in initial planning.

- Data & Demand Volatility: Predicting international demand accurately requires robust data and agile systems, especially when dealing with diverse cultural shopping holidays beyond Black Friday/Cyber Monday.

ModusLink’s Blueprint for Cross-Border Peak Season Success

This is where ModusLink’s end-to-end supply chain and e-commerce solutions become your strategic advantage. We specialize in transforming these challenges into opportunities for growth.

1. Proactive Duty & Tax Optimization: DDP Done Right

Avoid sticker shock and customs delays for your international customers. ModusLink’s expertise ensures your products move swiftly across borders. We help you implement Delivered Duty Paid (DDP) models, calculating and collecting duties, taxes, and fees at the point of sale. This transparency eliminates unexpected charges for your customers, boosting conversion rates and reducing abandoned carts. Our robust systems keep pace with changing regulations, minimizing your compliance risks.

2. Global Fulfillment Network & Agile Last-Mile Delivery

With a strategically located global footprint, ModusLink provides the infrastructure you need to reach customers anywhere. Our network allows for:

- Near-shore Inventory Placement: Reducing transit times and shipping costs by positioning your products closer to international demand hubs.

- Optimized Carrier Selection: Leveraging our extensive network of global and local carriers to select the most efficient and reliable last-mile delivery options, ensuring your products arrive on time for critical shopping events.

3. Seamless E-commerce & Financial Management

Beyond the physical movement of goods, ModusLink integrates the entire e-commerce journey:

- Localized Payment Solutions: Offering a wide array of local payment methods and managing multi-currency transactions, providing a frictionless shopping experience for your international clientele.

- Fraud Prevention: Implementing robust fraud detection to protect your cross-border transactions.

- Revenue Recognition: Streamlining the financial aspects of international sales, from order capture to settlement.

4. Simplified Global Returns Management

Don’t let returns erode your international profits or customer loyalty. ModusLink offers comprehensive reverse logistics solutions tailored for cross-border operations. We manage the entire process, from return authorization and shipping labels to quality checks and restocking, minimizing costs and improving the customer experience.

5. Data-Driven Insights & Demand Forecasting

Our integrated systems provide the visibility and analytics crucial for anticipating international demand fluctuations during peak season. By leveraging real-time data, we help you make informed decisions on inventory levels, optimize fulfillment strategies, and respond swiftly to market shifts.

Partner for Peak Performance

Q4 2025 will test every aspect of your supply chain. For brands aiming to expand their global reach and capitalize on the immense potential of international e-commerce, a robust, integrated partner is indispensable.

ModusLink’s deep expertise in global supply chain management, cross-border e-commerce, and financial management means you can focus on your core business – selling and growing – while we handle the complexities of getting your products to customers, wherever they are in the world.ourcing and logistics management to customs compliance and risk mitigation, we’re here to provide the expertise and support you need to navigate the complexities of global trade.

Bibliography

Source:

Google Gemini – Information was also provided by Google Gemni language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Tariff Tango: US Imports Brace for Summer Surge, Followed by 2025 Dip

Wooden tariffs stamp is sitting on recycled paper background. Horizontal composition with selective focus and copy space. The world of international trade is a complex dance, and right now, U.S. imports are performing a lively “tariff tango.” According to the latest Global Port Tracker report, a collaborative effort by the National Retail Federation (NRF) and maritime consultancy Hackett Associates, we’re about to see a significant surge in U.S.-bound imports this summer, primarily driven by a temporary reduction in tariffs on goods from China. However, this upbeat tempo is expected to slow down considerably as we head into the end of 2025.

The Summer Rush: A Window of Opportunity

Retailers are in their busiest season, preparing for both back-to-school and the crucial fall-winter holidays. Jonathan Gold, NRF’s Vice President for Supply Chain and Customs Policy, explains that many retailers had previously paused their purchases due to significantly high tariffs. Now, with the current reduction in tariffs on Chinese goods (set to expire in mid-August) and a pause on reciprocal tariffs from other nations (ending July 9), they’re scrambling to get merchandise into the country.

“Retailers want to ensure consumers will be able to find the products they need and want at prices they can afford,” Gold stated. This urgency means a flurry of activity at major U.S. ports, including Los Angeles/Long Beach, New York/New Jersey, Houston, and Savannah, among others.

A Rollercoaster of Numbers

The report highlights the volatile nature of import volumes. While April saw a 2.9% increase over March and a 9.6% annual rise in U.S. imports (totaling 2.21 million TEU), the projections for the coming months tell a different story:

- May: 1.91 million TEU (13.4% sequential decrease, 8.1% annual decrease) – marking the first annual decline since September 2023.

- June: 2.01 million TEU (6.2% annual decrease)

- July: 2.13 million TEU (8.1% annual decrease)

- August: 1.98 million TEU (14.7% annual decrease)

The most significant annual declines are anticipated from September through the end of 2025, largely due to the timing of import concerns over potential East and Gulf Coast port strikes a year ago. October is projected to see an 19.8% annual decrease at 1.8 million TEU.

Uncertainty Looms Beyond the Pause

Ben Hackett, Founder of Hackett Associates, aptly summarizes the current trade environment as “in a state of flux as it shifts from confusion to chaos and back again.” The temporary tariff reductions are a prime example of this unpredictability.

While the first half of 2025 is still expected to see a 3.7% annual gain in imports (12.54 million TEU), the outlook for the latter part of the year is more cautious. If higher tariffs are not delayed again after the current pauses expire, we can expect a noticeable decline in import volumes for the final four months of the year.

This situation underscores the critical need for stability and predictability in the supply chain. As retailers and consumers navigate these shifting trade winds, continued negotiations and clear policy from the administration are vital to ensure a smooth flow of goods and affordable prices.

In times of such flux, having robust and agile supply chain solutions is more critical than ever. At http://www.moduslink.com, we understand these challenges and offer comprehensive supply chain services designed to help businesses like yours adapt, optimize, and thrive amidst changing trade policies and market demands. From strategic sourcing and logistics management to customs compliance and risk mitigation, we’re here to provide the expertise and support you need to navigate the complexities of global trade.

Bibliography

Source: U.S.-bound imports expected to see tariff pause gains, followed by declines to end 2025, notes Port Tracker. By Jeff Berman, June 9, 2025.

OpenAI’S GPT-3 – Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Inventory Optimization in a Volatile Market: How to Stay Agile and Profitable

A supervisor with scanner in hands checking on goods in boxes in storage. In today’s unpredictable business environment, inventory is no longer just a cost center—it’s a strategic asset. From global supply chain disruptions to shifting consumer demand, businesses are facing increasing volatility. And with volatility comes the need for smarter, faster, and more flexible inventory management strategies.

Inventory optimization in a volatile market isn’t just about holding less stock—it’s about holding the right stock at the right time, in the right place.

Here’s how businesses are navigating these challenges in 2025—and how you can too.

📉 The Risk of Getting It Wrong

Poor inventory management in unstable conditions leads to:

- Stockouts, resulting in lost sales and damaged customer trust

- Overstocks, tying up capital and increasing holding costs

- Obsolete inventory, especially in fast-moving or seasonal industries

In volatile markets, these risks are amplified. Traditional forecasting models often fall short when consumer behavior, transportation costs, and supplier lead times are in flux.

📊 Key Strategies for Inventory Optimization in 2025

1. Leverage Real-Time Data and Predictive Analytics

Today’s inventory decisions need to be data-driven and dynamic. Modern supply chains are turning to AI and machine learning to:

- Analyze buying patterns

- Predict demand shifts

- Simulate supply chain scenarios

This enables more responsive planning and prevents knee-jerk decisions based on outdated information.

2. Implement Multi-Echelon Inventory Optimization (MEIO)

Rather than managing each node (warehouse, retail location, etc.) in isolation, MEIO looks at the entire supply chain network to balance inventory levels system-wide. This approach:

- Reduces total inventory across the network

- Increases service levels

- Enhances agility in response to disruptions

3. Segment Inventory Based on Demand Volatility

Not all inventory should be treated the same. Use ABC or XYZ analysis to segment products by demand variability and value. Prioritize high-value, high-volatility items for closer monitoring and frequent replenishment.

4. Strengthen Supplier Collaboration

In uncertain markets, your suppliers are part of your inventory strategy. Improve visibility and flexibility with:

- Shared forecasts

- Collaborative planning

- Buffer stock arrangements or vendor-managed inventory (VMI)

5. Adopt a Lean-but-Flexible Mindset

Striking the right balance between lean operations and risk mitigation is key. Build flexibility through:

- Safety stock where appropriate

- Decentralized inventory positioning

- Agile 3PL partnerships that allow quick scaling

🌍 Inventory Optimization Is a Competitive Advantage

As volatility becomes the norm—not the exception—companies that can continuously optimize inventory will outperform. They’ll respond faster to market shifts, serve customers more effectively, and operate with less waste and more capital efficiency.

At ModusLink, we help businesses achieve end-to-end inventory optimization through integrated fulfillment, data analytics, demand planning, and global logistics solutions. Whether you need greater visibility, Whether you need greater visibility, flexibility, or speed, our scalable services are designed to help you turn inventory into a strategic advantage.

Bibliography

OpenAI’S GPT-3 – Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

How Supply Chains Can Adjust to New Tariffs

Global Tariffs In the constantly shifting landscape of global trade, businesses are once again being tested by the resurgence of tariffs. With new policies affecting imports and exports across key markets—including the U.S. and China—supply chain leaders must move quickly to assess the impact and adapt their operations. Tariffs, while often imposed for strategic or political reasons, directly affect the cost of goods, the viability of certain supplier relationships, and ultimately, the bottom line. But while these challenges can be significant, they also present opportunities for smarter, more agile supply chain strategies.

Evaluating Tariff Exposure and Operational Risk

The first step in adapting to new tariffs is understanding where and how they will affect your business. Companies must dig deep into their supply chains to identify which components, materials, or finished goods are at risk of increased duties. This includes reviewing Harmonized Tariff Schedule (HTS) codes, validating country-of-origin data, and cross-checking trade classifications for accuracy.

In doing so, organizations can quantify their exposure and prioritize which products or sourcing strategies require immediate attention. A thorough analysis of import and export data, in combination with cost modeling tools, can highlight potential financial impacts—both direct and indirect.

Rethinking Sourcing and Supplier Diversification

For many, the answer to rising tariff costs lies in diversification. Relying on a single country or supplier can leave companies vulnerable not only to tariffs but also to broader geopolitical shifts. A diversified supply base provides flexibility—allowing businesses to shift sourcing strategies quickly in response to policy changes, economic instability, or natural disruptions.

This may mean qualifying secondary suppliers in countries not subject to new duties or exploring nearshoring opportunities to reduce exposure to long-distance trade risks. While diversification can require upfront investment in supplier vetting and logistics planning, the long-term benefit is a more resilient and adaptable supply chain.

Leveraging Free Trade Zones and Bonded Warehousing

Another effective strategy for mitigating tariff impacts is leveraging duty deferral programs, such as foreign trade zones (FTZs) and bonded warehouses. These solutions allow goods to be stored, assembled, or even manufactured in special zones without triggering immediate tariff costs. Duties are only paid when the goods enter the domestic market—or in some cases, are avoided entirely if goods are re-exported.

FTZs can also help streamline customs procedures and reduce paperwork, enabling companies to operate more efficiently while managing financial exposure. This is particularly useful for companies operating global distribution models or manufacturing in multiple regions.

Building Visibility Across the Supply Chain

Visibility is a critical enabler for any supply chain strategy—but even more so in an environment with fluctuating tariffs. Companies must have a clear, real-time view into their sourcing, production, and transportation networks in order to make proactive decisions. Without strong visibility, organizations may fail to respond quickly to tariff changes, miss opportunities to reroute shipments, or miscalculate inventory needs.

Advanced digital tools—such as supply chain control towers, integrated planning platforms, and collaborative supplier networks—help create the transparency needed to anticipate issues and take action before disruptions become costly delays.

Managing Inventory for Flexibility and Efficiency

Finally, companies should rethink their inventory strategies in light of tariff-related volatility. Carrying more buffer stock in key markets might offer some protection against import delays or cost spikes—but excessive inventory increases carrying costs and ties up working capital.

Balancing flexibility with efficiency requires a strategic approach. Scenario planning, demand forecasting, and real-time inventory monitoring can help companies identify the right levels of safety stock, as well as the most cost-effective locations for storing goods. Especially in industries with fast product cycles or tight margins, getting this balance right can make a major difference.

Conclusion: Building Smarter Supply Chains with the Right Partner

Adapting to new tariffs is not a one-size-fits-all challenge. It demands a tailored mix of strategic foresight, operational agility, and technical know-how. From reassessing global sourcing strategies to leveraging trade zones and improving end-to-end visibility, companies must be willing to evolve their supply chain strategies to stay competitive.

That’s where ModusLink can make a difference. With global reach, and deep operational expertise, ModusLink helps businesses navigate the complexities of trade regulations and build resilient, cost-effective supply chains. Whether you’re responding to new tariffs or preparing for the next market shift, ModusLink offers the tools and insights to turn disruption into opportunity.

Bibliography

OpenAI’S GPT-3 – Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Navigating the Impact of Global Tariffs on Your Supply Chain

Wooden tariffs stamp is sitting on recycled paper background. Horizontal composition with selective focus and copy space. The global business environment is constantly evolving, with tariffs emerging as one of the most significant changes in recent years. Tariffs, taxes imposed on imported goods, have a major influence on global trade, affecting businesses of all sizes. While tariffs are intended to protect domestic industries and generate revenue for governments, they also present significant challenges for companies that rely on international supply chains. This article explores the impact of global tariffs on your supply chain and offers strategies for minimizing their effects.

The Rising Cost of Goods: How Tariffs Affect Your Bottom Line

One of the most immediate impacts of tariffs is the increase in the cost of goods. When tariffs are imposed on imported raw materials, components, or finished products, the cost naturally rises. Companies face three main options to deal with the higher costs:

- Absorb the cost, reducing profitability.

- Pass the cost on to customers, which can affect pricing strategies and customer loyalty.

- Find alternate supply sources for the material and goods that are outside the affected tariffs.

This pressure on profit margins underscores the need for businesses to fully understand the financial impact of tariffs and take steps to minimize their burden. Carefully assessing how tariffs affect your cost structure is crucial for maintaining profitability and managing expenses effectively.

Key Takeaways:

- Tariff Impositions and Rollbacks: Changes to U.S. tariffs on key imports and exports could impact manufacturing costs. Companies that rely on raw materials, auto parts, and industrial components from Canada, Mexico, and China may experience price fluctuations.

- Trade Agreement Pressures: Although the United States-Mexico-Canada Agreement (USMCA) governs trade, ongoing tariff activity raises concerns about long-term stability. Some industries may seek exemptions, while others may face increased compliance requirements.

- Market Reaction and Business Uncertainty: Currency fluctuations, investor sentiment, and shifting trade flows may cause short-term disruptions in supply chain operations. Businesses that operate with just-in-time (JIT) inventory models are especially vulnerable to delays resulting from policy changes.

Disruptions in Sourcing and Delivery: Tariffs Cause Delays

Beyond cost increases, tariffs can also disrupt the timing of shipments and deliveries. Here are some ways tariffs can lead to delays:

- Customs Processing Delays: Additional documentation requirements can lengthen processing times at customs.

- Supply Chain Bottlenecks: Stricter customs inspections can delay shipments, disrupting inventory management.

- Inventory Shortages: Tariff-induced delays can lead to stockouts, making it difficult to meet customer demand.

Given today’s competitive market, meeting customer expectations for fast delivery is essential. Tariff-related delays can undermine customer satisfaction and damage your business reputation.

Mitigation Strategies: How to Reduce the Impact of Global Tariffs

To mitigate the challenges posed by tariffs, businesses can adopt several strategies to protect their supply chain operations:

- Diversify Your Supplier Base

Sourcing from countries with lower tariffs or favorable trade agreements can reduce the impact of tariffs. Exploring alternative suppliers in regions with lower or no tariffs minimizes costs and reduces exposure to tariff hikes. - Leverage Free Trade Zones & Tariff Classifications

Free trade zones (FTZs) provide a way to import goods without incurring tariffs, and sometimes with reduced duties. Additionally, understanding tariff classifications can help businesses lower duties on certain products, leading to cost savings. - Optimize Inventory and Demand Management

Proactive inventory management is crucial in the face of tariff-induced delays. Accurate demand forecasting and strategic inventory planning ensure businesses avoid stockouts and can capitalize on bulk purchasing before tariff increases take effect. - Collaborate with a Trusted Supply Chain Partner

Partnering with a trusted supply chain partner like ModusLink can help mitigate the impact of tariffs. ModusLink provides a global distribution network, technology, and automation that enhance real-time visibility, helping businesses forecast demand and manage their supply chains more efficiently.

Conclusion: Stay Ahead of Global Tariffs with Strategic Planning

Global tariffs present an ongoing challenge, but with strategic planning, businesses can successfully navigate these complexities. Understanding the impact of tariffs, diversifying suppliers, leveraging free trade zones, and collaborating with trusted partners are key steps in mitigating their effects. While ModusLink is not a tariffs expert, we are a supply chain services provider with 30 years of experience in helping businesses optimize their logistics and operations. By partnering with us, you gain access to our well-established logistics network, which can help you navigate tariff challenges by offering access to regions with favorable tariff conditions. With the right strategies in place, your business can remain adaptable, resilient, and positioned to thrive in an increasingly competitive global marketplace.

Bibliography

https://www.e2open.com/blog/trump-tariff-shifts-what-supply-c

OpenAI’S GPT-3 – Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.

-

Building Resilient and Agile Supply Chains: Key Strategies for Success

Supply Chain Management – SCM – The Coordinated Process of Producing and Delivering Goods and Services from Suppliers to Consumers – Conceptual Illustration In today’s rapidly evolving global marketplace, supply chain disruptions have become a regular occurrence. Factors such as geopolitical shifts, extreme weather events, raw material shortages, and infrastructure challenges can significantly impact operations. For businesses to remain competitive, they must not only respond to these disruptions but proactively build resilient and agile supply chains that can handle unforeseen changes.

A data-driven, holistic approach is essential to ensure that organizations stay agile, cost-effective, and resilient during times of uncertainty. In this blog, we’ll explore key strategies to enhance supply chain resilience and highlight how services like those offered by ModusLink can help businesses navigate these challenges effectively.

1. Effective Demand Planning and Forecasting

Accurate demand forecasting is the cornerstone of a resilient supply chain. By leveraging data analytics, businesses can better anticipate customer demand, optimize production schedules, and avoid both stockouts and overstocking. Predictive analytics tools can help identify shifts in consumer behavior, allowing businesses to respond proactively instead of reactively.

Effective demand planning also optimizes inventory levels, reducing costs associated with storage and carrying inventory. Companies that leverage tools like ModusLink’s demand forecasting solutions can gain real-time insights into market trends, enhancing their ability to meet customer demands efficiently.

2. Strong Supplier Relationships

The foundation of any successful supply chain lies in robust supplier relationships. Strong supplier partnerships lead to better collaboration, faster response times, and improved risk management. By building trust and establishing long-term agreements, businesses can benefit from greater flexibility, faster adjustments, and access to cost-saving opportunities.

ModusLink offers supply chain services that integrate supplier collaboration, enhancing visibility and supporting faster and more efficient decision-making. Their platform facilitates communication across various stages of the supply chain, helping to identify and resolve disruptions.

3. Inventory Optimization

Balancing inventory levels is crucial for maintaining an efficient supply chain. Too much inventory ties up capital and incurs unnecessary storage costs, while too little can lead to missed sales opportunities and frustrated customers. By optimizing inventory levels, businesses can reduce costs, improve cash flow, and ensure consistent product availability.

ModusLink’s inventory management solutions help businesses streamline this process. With advanced analytics and automation, ModusLink enables companies to balance their inventory to meet demand while reducing the risk of stockouts or excess inventory. This approach not only improves operational efficiency but also enhances customer satisfaction through reliable product availability.

4. Logistics Efficiency

Logistics plays a critical role in ensuring that products reach customers quickly and reliably. Efficient logistics operations reduce lead times, cut transportation costs, and improve customer satisfaction. Real-time tracking and route optimization are essential tools for enhancing delivery efficiency and managing costs.

With ModusLink’s logistics services, companies can optimize their distribution networks, track shipments in real time, and reduce operational costs. Their expertise in managing complex logistics systems ensures that goods are delivered on time, regardless of disruptions. Additionally, ModusLink’s global network helps businesses scale and reach international markets with ease.

5. Agility and Flexibility

One of the key characteristics of resilient supply chains is their ability to quickly adapt to changes in demand, disruptions, or new market opportunities. Achieving agility requires a flexible supply chain with diversified sourcing, scalable manufacturing, and adaptive logistics strategies.

ModusLink supports this agility by offering customizable supply chain solutions that allow businesses to scale operations quickly. Whether you need to ramp up production or pivot to a new sourcing model, ModusLink’s flexible infrastructure ensures that your business remains adaptable and responsive to changes in the market.

6. Risk Management and Resilience

Effective risk management is essential for building a resilient supply chain. Identifying and addressing potential risks—whether they involve suppliers, geopolitical instability, or natural disasters—is key to minimizing disruptions and ensuring business continuity. Proactive strategies such as multi-sourcing, maintaining safety stock, and developing contingency plans help businesses prepare for and manage unforeseen challenges.

ModusLink supports businesses in navigating these risks by providing comprehensive supply chain solutions that prioritize risk mitigation. With their global network and expertise, companies can better anticipate disruptions and implement strategies to minimize the impact of unforeseen events, helping to maintain continuity even during times of uncertainty.

7. Technology Integration

Incorporating advanced technologies into supply chain operations can significantly improve transparency, efficiency, and decision-making. Technologies such as cloud-based platforms, enterprise resource planning (ERP) systems, and automation solutions are key tools that help optimize supply chain performance.

Cloud-based platforms enable real-time data sharing and improve coordination between stakeholders, including suppliers, manufacturers, and distributors. Enterprise Resource Planning (ERP) systems provide an integrated solution for managing essential business processes such as inventory, procurement, production, and order fulfillment. By centralizing data and operations, ERP systems streamline workflows, reduce manual errors, and increase operational efficiency across the supply chain.

Automation technologies, whether in warehousing, inventory management, or order fulfillment, are transforming the way businesses operate. Automation helps reduce human error, accelerates processes, and ensures accuracy in inventory and order tracking. As a result, businesses can achieve faster, more reliable delivery times, leading to improved customer satisfaction.

ModusLink integrates these advanced technologies into supply chain operations, providing businesses with the tools to enhance visibility, improve efficiency, and streamline coordination. By leveraging these technologies, companies can stay agile and better prepared to respond to disruptions, ensuring smoother and more resilient operations.

8. Sustainability and ESG Integration

As consumer demand for eco-friendly and socially responsible products increases, businesses must prioritize sustainability within their supply chains. Sustainable practices—such as reducing emissions, minimizing waste, and sourcing ethically—are essential for building a resilient and future-proof supply chain.

ModusLink’s sustainability initiatives help businesses implement green practices throughout their supply chains. From optimizing packaging to reducing carbon emissions in transportation, ModusLink’s services align with the growing demand for responsible business practices, helping companies meet Environmental, Social, and Governance (ESG) goals while enhancing brand reputation.

Conclusion

Building a resilient and agile supply chain requires a strategic combination of effective demand planning, strong supplier relationships, optimized inventory, efficient logistics, and advanced technology. Services like those offered by ModusLink provide businesses with the tools they need to enhance visibility, streamline operations, and mitigate risks. Whether it’s improving collaboration with suppliers, optimizing inventory management, or embracing digital transformation, a holistic approach to supply chain management ensures that businesses are ready to thrive in today’s fast-changing landscape.

By implementing these strategies and leveraging the right tools, businesses can turn their supply chain into a competitive advantage—ensuring long-term growth and success. To learn more about how ModusLink’s solutions can help you build a more resilient and efficient supply chain, visit their website or explore their range of services.

This expanded approach, supported by ModusLink’s expertise, enables organizations to create a supply chain that is not only cost-effective but also adaptable, sustainable, and resilient in the face of global challenges.

Bibliography

https://www.ivalua.com/blog/top-supply-chain-strategies

OpenAI’S GPT-3 – Information was also provided by OpenAI’S GPT-3 language model.

Disclaimer:

Content is the opinion of ModusLink Corporation and is not intended to act as compliance or legal advice.