-

Innovation with Reverse Logistics (Part 2 of 2)

Introduction

Many SMEs (small and medium enterprises) now make use of reverse logistics to some degree as they work with omni carriers and shippers and service providers. Many end-to-end processes are involved with reverse logistics, including omnichannel logistics warehouse management, real-time shipment tracking, innovative communication options, integrated technology, and smart supply chain tools and platforms.

The benefits gained, such as resource management, profit margin increase, and increased customer satisfaction, are prominent within any company that maintains reliable reverse logistics management within the supply chain.

From a supplier point of view, reverse logistics aims at dealing with leftover products, waste, raw materials, and returned goods that are not required by end customers. Environmental concerns are strictly linked to customers’ demand for more sustainable products and economic benefits since a returned item can easily be sold instead of producing a new one from raw materials (D’Amico, E. D. 2021).

Here experts will cover the latest innovations mainly used to gain a competitive advantage within the marketplace. When executed correctly, these innovative technologies allow companies to scale rapidly.

.

How Omnichannel Logistics Warehouse and Logistics Management Helps Reverse Logistics

SMEs often outsource to professional supply chain companies that make use of these technologies. SMEs can experience the benefits of rapid scalability while keeping investment costs low. It also provides better resource management. In this article, we will zoom in on the popular innovations that are helping to shape omnichannel logistics warehouse operations and logistical processes.

According to D’Amico, E. D. (2021), An implementation of technologies such as IoT (Internet of Things) and blockchain would allow for improvement in the functionality of reverse logistics. Everything from warehousing to shipping management to inventory logistics all can be improved with the right tools and technology. Every step in the process will carry positions of power unique to the individual supply network, meaning management and insight is more important than ever.

Although these technologies can be expensive to implement and require much expertise, they offer possible solutions, especially with RFID (Identification tags usable on products). Traceability, transparency, and prediction are the main benefits of a Smart Reverse Supply Chain (SRSC).

All this can easily be accomplished with innovative technologies, tech stacks, and new ways for omni carriers and shippers to embrace digitalization and automation. In the end, this translates to higher profits, lower costs, fewer fraud management concerns, and improved productivity overall.

Internet of Things (IoT)

The IoT describes a network in which every physical product has a virtual identity and is linked to a connection. It represents one of the main pillars of the revolution of the omnichannel supply chain.

The IoT is the key that allows omnichannel logistics warehouse objects, such as tracking and monitoring barcodes, tags, or sensors, to communicate with each other and humans. The holistic connection created a synergized network that allows streamlined data transfers on a large scale.

IoT is used within many supply chain aspects nowadays. Inventory management is a frequently used aspect. As soon as the quantity falls under an established number, a reorder can be automatically processed using RFID in a virtual cloud.

According to industry experts, the structure of IoT for omni carriers and providers is based on four layers of services that focus on the proper disposal of products and materials and the overall management of reverse supply chain logistics. These are:

- Data storing (RFID) initiated at the point of origin

- Communication between involved parties

- Services focused on smart contract and logistics

- Display data and share information effectively

IoT is able to bring remarkable opportunities to reverse logistics and provide valuable resource leveling power and insight into the logistics of this unique logistical flow. The information infrastructure is strongly improved by establishing a connected network of products (Gar-2020).

Blockchain

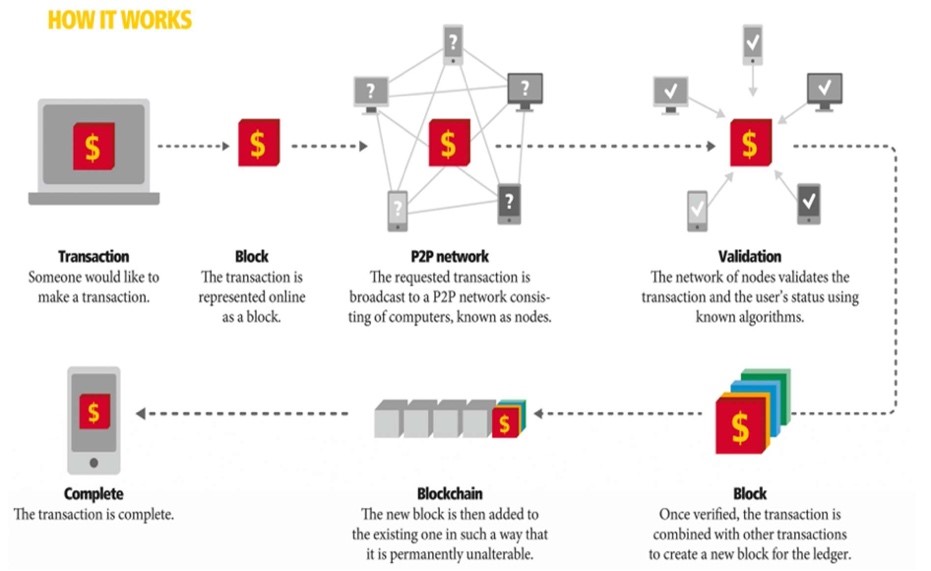

Blockchain can be defined as a digital technology that facilitates the recording of transactions and allows for the traceability of a resource.

The resource type can vary between physical (e.g., cars) or abstract resources (e.g., patents or cryptocurrency). This is especially true with cryptocurrency, blockchain allows the record of every transaction and helps fraud management.

The main concept stimulates the idea of handling information in a decentralized way. Private blockchains and public blockchains alike can help improve supply chain returns process management. The information is supported by the collective instead of by a single entity, improving its resilience and impact overall.

When it comes to supply chain and reverse logistics management, blockchain digital currency and processes can be used to improve the chain in multiple ways. The decentralized structure allows every logistics member to keep real-time track of a product and increases the data’s reliability (Zhu-2019). The transparency enabled by blockchain increases the security of trade.

This security is a valuable element needed in any resilient supply chain. In addition, blockchain allows networks to streamline their transaction process as it can remove intermediate steps from the transactional process. This reduces costs and time, ultimately improving the supply chain.

The figure below clearly illustrates the blockchain process as it relates to omnichannel logistics warehouses and returned products management.

The figure below clearly illustrates the Blockchain process.

Figure 1. (The Blockchain process) D’Amico, E. D. (2021, October 10).

Boost Omnichannel Supply Chain Reverse Logistics Today

Bringing together omni carriers and shippers and service providers is an integral part of reverse logistics management. Would you like to know more about these innovative technologies and how to master the reverse logistics process for your business? The answer to better supply chain management and returns logistics is right here.

It is easy to boost project management processes and develop effective reverse logistics when you have the tools and technology at hand. Let the industry leaders demonstrate how easy returns management can be with the right resource management software and the latest innovative tools in play. Contact a ModusLink expert today to get started!

Bibliography:

D’Amico, E. D. (2021, October 10). ResearchGate. ResearchGate. Retrieved November 6, 2021, from https://www.researchgate.net/publication/354551628_Analysis_of_Challenges_and_Potentials_of_Reverse_Logistics

Jenkins, A. (2021, April 5). A Guide to Reverse Logistics: How It Works, Types and Strategies. Oracle NetSuite. https://www.netsuite.com/portal/resource/articles/inventory-management/reverse-logistics.shtml

Marchese, K. (2021, October 29). Supply Chain leadership. Deloitte United States. https://www2.deloitte.com/us/en/pages/operations/articles/supply-chain-leadership.html

Niroomand, I. (2021, August 31). The importance of reverse logistics in your supply chain network. Kinaxis. https://www.kinaxis.com/en/blog/importance-reverse-logistics-supply-chain-network

Reverse Logistics – Rhenus Netherlands. (n.d.). Rhenus. Retrieved November 6, 2021, from https://www.rhenus.com/en/nl/our-solutions

-

Innovation with Reverse Logistics (Part 1 of 2)

Introduction

Meta-description. Understanding the reverse logistics meaning helps shippers to account for changes in consumer behaviors and reduces risk. Learn how today.

When speaking to any experienced supply chain professional, the focus on reverse logistics e-commerce can be expected somewhere within the conversation. A strong supply chain must contain elements such as resilience, agility, responsiveness, cooperation, fluency, and so forth. Managing to maintain all these elements can be highly challenging. However, if a business succeeds, the rewards are highly noticeable and can be far-reaching and highly impactful. This is why understanding the reverse logistics meaning in the modern e-commerce supply chain network is more vital than ever!.

Understanding the Importance of Reverse Logistics Management Today

Loyal customers, fast delivery, capability to adapt to the market, freedom in spending resources, time management, effective return management, improved logistics warehouse features, and more all impact reserve logistics.

Statistics from the past year or two do not lie, as highlighted by 2022 reports from Zippia: “38.8% of U.S. small businesses experienced supply chain delays due to the COVID-19 pandemic. The global supply chain market size value is $15.85 billion. And the global supply chain market is expected to experience a CAGR of 11.2% from 2020 to 2027.”

SMEs (Small/Medium Enterprises) often struggle to effectively manage their supply network due to limited capacity and resources. A popular solution to this can be given in the form of Outsourcing. Many SMEs take advantage of outsourcing important tasks and processes of their reverse logistics to experienced professionals within the industry.

A strong focus on reverse logistics e-commerce allows businesses to quickly scale their services and invest their time and resources into other parts of the company. And best of all, this can happen without sacrificing the importance of the key driver behind their business, the modern omnichannel supply chain.

A significant element often prioritized when outsourcing these processes is reverse logistics, which means understanding reverse logistics meaning can have deep-reaching implications for supply chain managers. This is because the element greatly impacts the customer satisfaction ratio and overall supply chain performance.

The definition of Reverse Logistics

Reverse Logistics is often referred to as Reverse Supply Chain, and part of ‘Closed Loop Supply Chain’. Its first definition was published only in the beginning of the nineties by the Council of Logistics Management (Bri-2004, S. 4) and thus still represents a young sector of Logistics.

Reverse logistics, when focused on goods and services, deals with the process of planning, implementing, and controlling the flow of shipments from the back through the supply line (Bri-2004, S. 5). It is essentially the logistics of dealing with a returned item or product.

Figure 1(The Reverse Logistics Process) (Chi-2018)

The Figure above clearly illustrates the core elements of the Reverse logistics Process. Products are received from the end-customer and transported back to the warehouse in question. They are then carefully inspected for defects, depending on the reasoning behind the return. They are then adequately sorted and either resold/recycled or scrapped.

The Introduction of Reverse Logistics e-Commerce Within Supply Chain Management

Businesses often quickly experience the challenges of reverse logistics, such as capacity management, customer expectations, waste management, and more. These challenges were often too grand to build a reliable reverse logistics process due to limitations with logistics warehouse systems and ineffective tech stacks.

Only recently has reverse logistics become increasingly popular to manage effectively. There are a couple of reasons for this. The uprising of eCommerce businesses is one explanation, as many products flow quickly through an eCommerce business, increasing the importance of managing the returns process. This has further fueled the need for a clear understanding and visible insight into reverse logistics meanings in light of continued focus on The Internet of Things (IoT)and other automations.

Another reason for the increase in the popularity of reverse logistics management is the rise of substantial technological solutions and innovations, such as the IOT and drones or autonomous guided vehicles (AGVs or drones). These reverse logistics e-commerce solutions allow SMEs to overcome the challenges that come with effectively managing a reverse Logistics process.

Smart Reverse Supply Chain (SRSC)

The concept of merging the technology mentioned above, together with Reverse Logistics forms the idea called a ‘Smart Reverse Supply Chain.’ Smart management of reverse supply chain logistics can save a lot in terms or wasted time and money. It can also improve customer experience and streamlining the process of returning goods flowing back through the supply chain.

To overcome the challenges that come with managing these processes, businesses decide to make use of technologies such as automated inventory tracking, warehouse monitoring, real-time communications, and digitalization and automation of all sorts.

They can choose to adopt these logistics warehouse tools and technologies individually, or collectively make them work together to strengthen the synergy within the reverse supply chain.

SRCS can manage flow times and information exchanges more effectively between logistical partners. This minimizes the uncertainties and difficulties when returning products. Xu (Xu-2011b) can be equipped with a unique identity and communicate with other devices.

The two key elements that ought to be managed effectively to improve SRCS are:

- Identification tools: To implement a well-organized smart reverse logistics, it is necessary to establish appropriate identification methods such as RFID (ID Tags), 3-D and 4-D Barcodes to permit the recognition of incoming and handled objects and the communication between them. It also allows for better comprehension of reverse logistics meanings.

- Standardization: To allow every member of the Closed Loop Supply Chain to process and identify the products, it is necessary to establish a standardization of the used technologies. Although there are governing bodies that keep reverse logistics e-commerce, uniform technologies need to be standardized and improved to meet growing needs and demands.

Improve Reverse Logistics and Profitability With ModusLink

These two elements are best managed through innovative technologies such as chatbots, real-time tracking, push notifications, reliable scanning, and supply chain tools that leverage the IoT. Doing so opens the door to even more amazing possibilities, including drones in supply chain networks, automated vehicles, and more!

Would you like to know more about these innovative technologies and how you are able to implement these within your supply chain? Ready to learn how to make logistics warehouse operations and existing processes more efficient?

To better understand reverse logistics meanings and the impact logistics and management can have on your supply chain network, contact ModusLink today!

Bibliography:

Kolmar, Chris (2022, October 24). 18 STUNNING SUPPLY CHAIN STATISTICS [2022]: FACTS, FIGURES, AND TRENDS, Accessed October 24, 2022 From https://www.zippia.com/advice/supply-chain-statistics/

D’Amico, E. D. (2021, October 10). ResearchGate. ResearchGate. Retrieved November 6, 2021, from https://www.researchgate.net/publication/354551628_Analysis_of_Challenges_and_Potentials_of_Reverse_Logistics

Jenkins, A. (2021, April 5). A Guide to Reverse Logistics: How It Works, Types and Strategies. Oracle NetSuite. https://www.netsuite.com/portal/resource/articles/inventory-management/reverse-logistics.shtml

Marchese, K. (2021, October 29). Supply Chain leadership. Deloitte United States. https://www2.deloitte.com/us/en/pages/operations/articles/supply-chain-leadership.html

Niroomand, I. (2021, August 31). The importance of reverse logistics in your supply chain network. Kinaxis. https://www.kinaxis.com/en/blog/importance-reverse-logistics-supply-chain-network

Reverse Logistics – Rhenus Netherlands. (n.d.). Rhenus. Retrieved November 6, 2021, from https://www.rhenus.com/en/nl/our-solutions/contract-logistics/logistics-solutions/reverse-logistics/