Understanding the concept

According to ModusLin e-business and CRM leader, Johannes van den Berg, “Having your manufacturing strategy align with your customer’s needs and wishes creates synergy within a business. This results in increased production efficiency and growth as well as improved risk management and end-to-end improvements.”

There are many different manufacturing strategies that use aftermarket support and warehousing technology to improve distribution, customer experience, lead times, and warehouse operation.

At the core of successful supply chain management is warehouse and distribution management processes A report published by Comparative European Research titled ‘The growing importance of the synergy effect in a business environment perfectly explains the synergy concept. Synergy is a core element present in many successful manufacturing strategies and helps with meeting customer needs and demands.

It is a connection/interaction between different elements within a specific environment, creating or subtracting the additional value in the process. Improved tools and technology, such as digitization and automation, along with machine learning and AI processes, are all part of improving synergy within the supply chain network.

How does this relate to businesses today and improved supply chain and direct distribution services? Let’s find out!

Warehouse and Distribution Strategies Explained

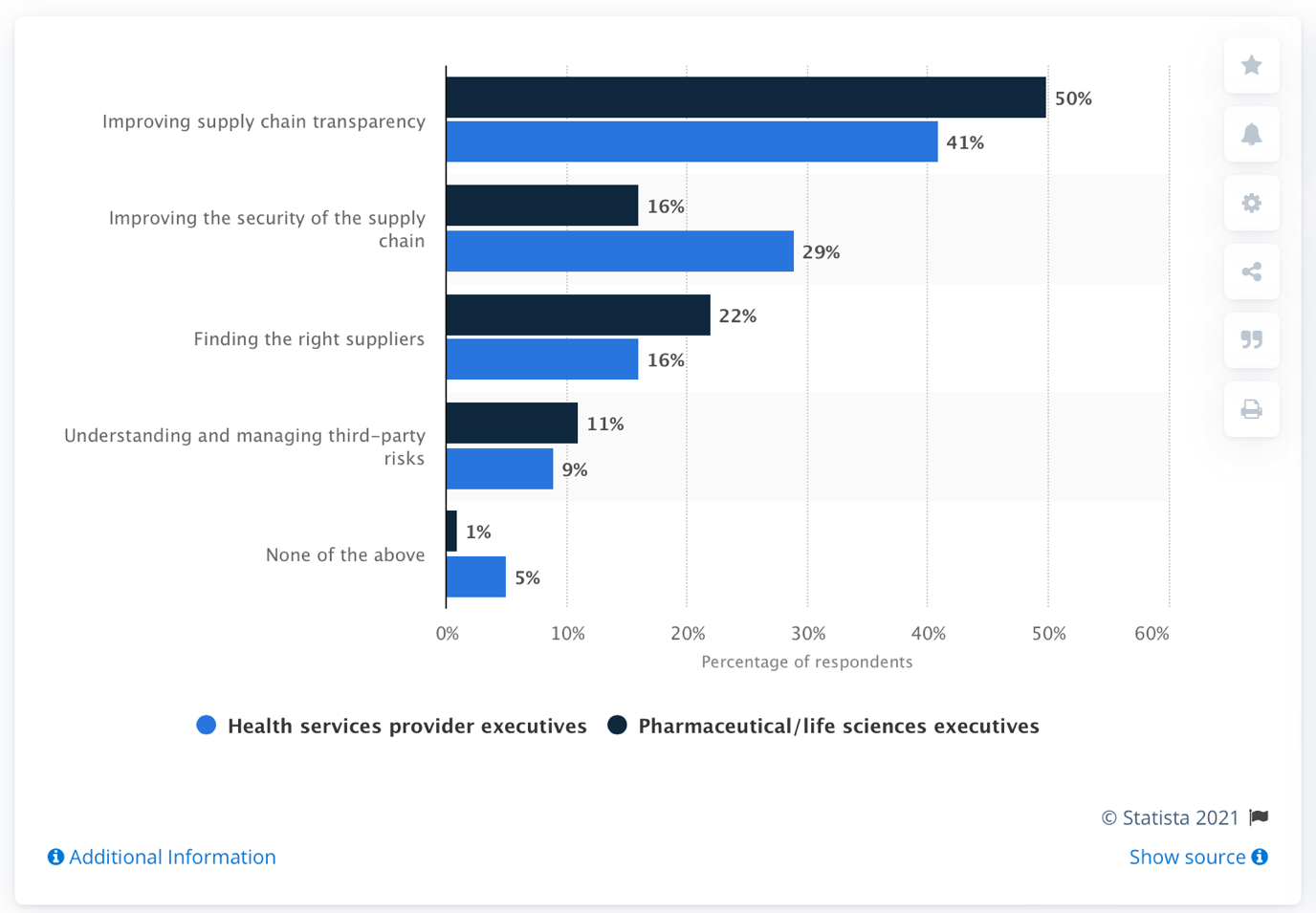

The importance of a proper manufacturing strategy and aftermarket support approach are indisputable. The three main Supply Chain priorities reported by U.S. health services providers and pharma/life sciences executives for 2021 are the improvement of Supply Chain transparency, improving Supply Chain security, and finding suitable suppliers (Statista, 2021).

The three elements relate to manufacturing strategy. Close contact with your supplier of raw materials is necessary when implementing the above manufacturing strategies. Reinforcement of supplier relations plays a crucial part in direct distribution, route management, and supply production processes.

Managing inventory properly using principles as JIT reinforces security within your Supply Chain and consequently can increase transparency when closely involving your suppliers.

Figure 1. (Top Supply Chain Priorities 2021) Statista. (2021, January 26). Supply chain priorities of U.S. provider and pharma/life sciences executives 2021. https://www.statista.com/statistics/1196032/supply-chain-priorities-health-services-provider-and-pharma-executives/

Different Strategies for Improved Aftermarket Support and Direct Distribution

Managing warehouse and distribution, supply chain logistics, supply lines, and shopping modes and trends are essential to improving distribution and support. It is easier to avoid issues such as supply chain attacks and weaknesses with the right strategy in place.

Here are three key strategies omnichannel supply chain management teams can use to improve aftermarket trends and demand forecasting methods today:

- Make to Stock (MTS)

This strategy is prominent in many businesses as it utilizes traditional production based on demand forecasting. Companies choose this manufacturing strategy because of the predictable demand forecasting that comes with certain products. For instance, winter coats are known to be purchased during winter, increasing the demand predictability.

Companies can thus safely create and stock winter coats before they are purchased. Unpredictable demand does not incentivize this strategy, as excess inventory can accumulate significant problems. Aftermarket support becomes easier and more straightforward and benefits customers and managers alike.

- Make to Order (MTO)

Some companies that use this strategy put manufacturing on hold until an order is received, minimizing stock levels. This strategy provides strong inventory and market control and aids managers in trend projection and the protection of sensitive data from clients and third parties.

A constant and minimal stream of orders must be present to maintain the production facility in question. Customer waiting times are also significantly longer (TheBusinessProfessor, n.d.) and can be impacted by warehouse and distribution and supply chain tools and tech.

- Make to Assemble (MTA)

This strategy involves the making of product parts before orders are received. The MTA strategy is a combination of MTO and MTS manufacturing strategies. Here product parts are stocked, yet the final product is assembled only when an order is placed and processed.

This strategy is often seen in restaurants as ingredients get prepared beforehand. Yet, the final dishes are assembled only when an order comes in to keep the dish fresh and flavorful.

No matter the inner workings, these three strategies play an integral role in supply chain management and direct distribution today.

Improve Warehouse and Distribution Performance With Help From ModusLink

The MTS, MTO, and MTA manufacturing strategies form the core strategies used by most businesses. These strategies are built upon principles such as the Just-In-Time (JIT) approach that focuses on eliminating waste by ensuring minimal stock levels are held through (party) automated product reordering systems.

John Heffernan, Chief Supply Chain Officer at ModusLink believes, “maximizing the efficiency of your manufacturing strategy is of high importance as it will yield waste reduction and a more streamlined production process, optimizing your supply chain.” And, it’s true; improving warehouse management, manufacturing strategies, direct distribution, and aftermarket customer support are critical to ongoing growth and recovery today.

Need professional advice on the right manufacturing strategy/optimization? Looking for ways to improve aftermarket support and internal distribution and management processes? Contact one of ModusLink’s Industry experts today.

Bibliography:

Comparative European Research. (2016, October). The growing importance of synergy effect in business environment(No. 1). Sciemcee Publishing. https://www.researchgate.net/publication/315657493_The_growing_importance_of_synergy_effect_in_business_environment

Manufacturing Production. (n.d.). Investopedia. Retrieved August 27, 2021, from https://www.investopedia.com/terms/m/manufacturing-production.asp

TheBusinessProfessor. (n.d.). Manufacturing Production (Strategy) – Definition. The Business Professor, LLC. Retrieved August 27, 2021, from https://thebusinessprofessor.com/en_US/business-management-amp-operations-strategy-entrepreneurship-amp-innovation/manufacturing-production-strategy-definition

Statista. (2021, January 26). Supply chain priorities of U.S. provider and pharma/life sciences executives 2021. https://www.statista.com/statistics/1196032/supply-chain-priorities-health-services-provider-and-pharma-executives/